Poor inventory management is one of the biggest problems that can doom a business selling physical products – stock levels can be easily maintained as you evolve your inventory management process.

Your small business will only be successful if you have a product or a service to sell.

Let’s look into the meaning of inventory management, its importance, and tips to evolve inventory management.

What Is Inventory Management?

Inventory management refers to optimizing your inventory space. Inventory management is the art of optimizing your inventory space and only carrying items that are selling.

The inventory management process also involves implementing a system that reduces errors and streamlines the shipping and receiving process. It will ultimately lower your spending and increase your free cash flow.

What Is The Importance Of Inventory Management?

There are a few benefits to inventory management. The most obvious on evolving your inventory management process is the reduction of the possibility of running out of valuable products.

By engaging in well-organized inventory management, you optimize spaces in your warehouse and reduce unnecessary inventory.

If you are good at inventory management, you will know what is selling well and avoid carrying too many of those items moving forward. You can also evade renting out or buying space that you don’t use, which reduces your real estate expenses.

You can manage your inventory to keep your cash flow healthy by ensuring you have products that are in high demand. If you don’t sell the products customers want, it’ll be tough to earn profits.

Good inventory management includes storing the correct amount of raw material. If you have a good idea of the number of raw materials your business requires, you can purchase in bulk to save per-unit costs.

This will reduce inventory costs and allow you to earn more profit.

Tips To Evolve Inventory Management

- The ABC analysis is your guide

- An inventory management system reduces human error

- Do some housekeeping in warehouse management

- Supply chain management is a must

- Don’t keep excess inventory/stock

- Create a reorder point

The ABC Analysis Is Your Guide

Before you can optimize and adjust it, the first thing to do is establish an inventory management process.

ABC analysis is one of the most straightforward inventory management systems you can implement and expand. It separates your warehouse items into three different categories.

- A: A priority for your business is A. Consider items that generate the highest profit directly or indirectly. These raw materials are vital for the production of your products, and you cannot afford to run out.

- B: Although your B items may not be as valuable as A items, they are still important. These items could include less-expensive, less-used raw materials or items that aren’t sold as often or at a higher margin. You will likely want to keep some stock of B items.

- C: Even though they are not very valuable, the C items can still be a key part of your company’s success. These inventory items can be finished products or incredibly cheap raw materials. While you will likely have many C items, their real value is low.

There are many types of inventory that can fall within the above categories. They range from low-cost products and raw materials to high-dollar items with low quantities.

Consider your physical inventory space. Consider how your business would be affected if you had too many or too few items in each category. This will allow you to determine the appropriate group for each item.

An Inventory Management System Reduces Human Error

Humans are human. Humans make mistakes. Although mistakes are usual and expected, they can also be a problem to inventory management. Software and apps for inventory management can help reduce human error.

To eliminate the tedious work of manually tracking inventory on paper with the right inventory tracking software, you must use intuitive inventory software.

Ensure your team is well trained so inventory management becomes faster and more efficient.

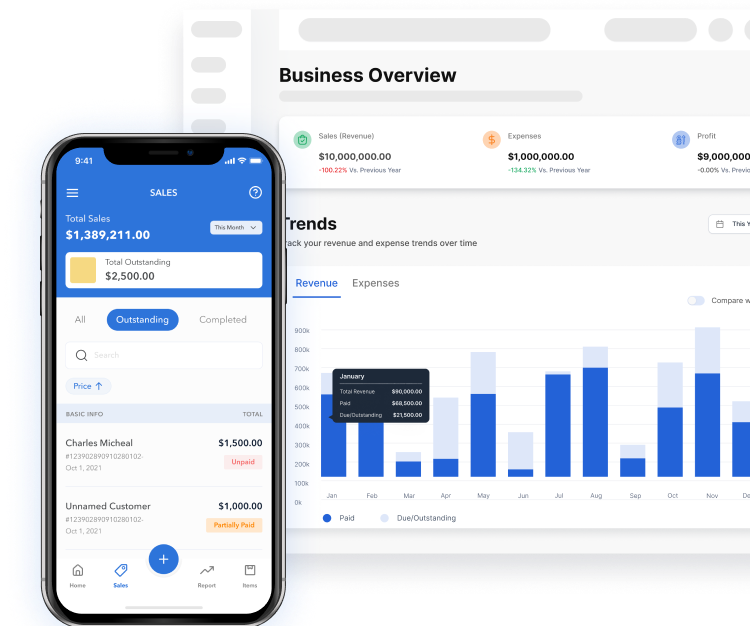

An Inventory Management System like Vencru can help you manage all your products. You can track your finances and ensure you are not spending extra money on overstocking.

Along with inventory management, you get accounting software and invoicing software for your small business with Vencru.

Do Some Housekeeping In Warehouse Management

A poorly managed warehouse is dirty. Proper housekeeping is key to inventory management.

Keep your warehouse orderly to avoid expensive errors, delays in shipment, and other related problems.

You should designate an area to receive, ship, and fulfill sales orders as you might consider color-coding shelves and taping off staging areas to accommodate certain product types.

A cleaning schedule should be available to ensure that your warehouse is well kept clean and maintained.

Supply Chain Management Is A Must

If your supply chain is chaotic, all the inventory management strategies will not help. Supply chain management is crucial.

Supply chain management refers to the process of optimizing and managing your relationships with material providers, dropshipping partners, and other parties involved in your inventory lifecycle.

It’s all about the time it takes to request an order, initiates a process, or complete the action. You should contact your supply chain partner if you find a bottleneck in the production, shipping, or receiving process.

Don’t Keep Excess Inventory/Stock

Every inch of your business is valuable, as well as the storage space. To avoid overstocking on high-demand products, you should only keep the necessary products.

Do inventory audits and examine your sales logs. It will allow you to identify which items are selling, which are deadstock, and which stock is simply taking up space. It’s also a good idea to practice just in time (JIT) production. This allows you to keep as few raw materials as possible and only order what you need to finish production.

This will lead to a reduction in costs and save you space for other products

Create A Reorder Point

The point you place an order for more product or material is called a reorder point. A reorder point allows you to maintain healthy inventory levels without the need to monitor them constantly.

You can usually set up an automatic reorder point with the right inventory management software.

You’d have to adjust your reorder points over time. Customers’ demands change over time.

A constant-selling product that was popular a year ago might not be available tomorrow. Do not forget to set a reorder level.

Check your stock levels regularly to determine if any items are not selling. This is a sign that you may be able to lower your reorder points and free up storage space for something more valuable.

Final Takeaway

Inventory management is a must for your business. If you are running an online business, eCommerce is made significantly easier with inventory management.

There are various steps you can take and tips you can use to improve inventory management for business.

Sign up with us today and evolve your inventory managerial processes!