To run a successful wholesale business, effective inventory management is crucial to maintain a competitive edge and maximize profitability. With the right strategies and tools in place, wholesale businesses can minimize stockouts, reduce holding costs, and ensure smooth operations.

In this blog post, we’ll explore seven actionable tips to help wholesale admins, managers, and business owners optimize their stock management process.

Why is Wholesale Inventory Management Important?

Efficient inventory management is pivotal for wholesale businesses, impacting profitability, customer satisfaction, and operational efficiency. Here are some reasons to adopt effective inventory management:

- Maximizing Profitability: Optimizing stock levels minimizes overstocking. Thus, freeing capital for growth initiatives and reducing holding costs.

- Enhancing Customer Satisfaction: Accurate inventory tracking ensures products are available when needed. This fosters trust and repeat business hence, increasing sales.

- Optimizing Efficiency: Streamlined processes and automation reduce errors, saving time and resources for core activities. This enhances productivity.

- Minimizing Holding Costs: Efficient inventory practices reduce excess inventory. Consequently, lowering holding costs and improving cash flow.

- Staying Competitive: Adapting to market changes and leveraging real-time data keep businesses agile. This helps your business stay ahead of the competition.

Related Read: Inventory Management: 6 Tips To Evolve Your Inventory

What are the Challenges in Wholesale Inventory Management?

Managing inventory in wholesale operations presents several hurdles that require strategic solutions for smooth operations and increased profitability. Some of these are:

- Demand Forecasting: Accurate demand forecasting is hindered by market fluctuations and shifting consumer preferences, which impacts customer satisfaction and profitability.

- Inventory Optimization: Balancing stock levels to meet demand while minimizing costs is crucial for avoiding overstocking or understocking, necessitating robust inventory strategies.

- Supplier Management: Supplier relationships are key, yet challenges like late deliveries and quality issues can disrupt operations, highlighting the need for effective communication channels.

- Inventory Accuracy: Accurate inventory records are essential for efficient operations, requiring automated tracking systems to minimize errors and discrepancies.

- Warehouse Management: Efficient warehouse operations are vital, but inefficient layouts can lead to errors and delays, necessitating investments in optimized workflows.

- Regulatory Compliance: Compliance with regulations is essential but demanding, requiring robust processes and staying informed about regulatory updates.

Related Read: 10 Inventory Software for Wholesale Distributors

7 Ways to Optimize Wholesale Stock

- Understand Your Demand Patterns

- Invest in Inventory Management Software

- Implement Just-in-Time (JIT) Inventory Practices

- Utilize ABC Analysis for Stock Prioritization

- Establish Effective Supplier Relationships

- Embrace Automation and Technology

- Monitor Key Performance Indicators (KPIs) Regularly

1. Understand Your Demand Patterns

To ensure you have the right products in stock at the right time, it’s essential to analyze your demand patterns. By leveraging historical sales data and forecasting techniques, you can accurately predict future demand and adjust your inventory levels accordingly. This proactive approach helps prevent overstocking or understocking situations, ultimately improving customer satisfaction and higher sales.

2. Invest in Inventory Management Software

Investing in specialized inventory management software tailored to the wholesale industry can significantly streamline your operations. Look for features such as real-time tracking, customizable reporting, and integration with other business systems. With the right software, you can automate repetitive tasks, gain valuable insights into your inventory performance, and make data-driven decisions to optimize stock levels.

Related Read: 5 best inventory management software for Wholesale business

3. Implement Just-in-Time (JIT) Inventory Practices

Just-in-Time (JIT) inventory management focuses on minimizing excess inventory by ordering and receiving goods only when needed. By adopting JIT practices, wholesale businesses can reduce carrying costs, free up valuable warehouse space, and improve cash flow. However, having strong relationships with reliable suppliers and efficient logistics processes is crucial to ensure timely deliveries and prevent stockouts.

4. Utilize ABC Analysis for Stock Prioritization

ABC analysis categorizes inventory items based on their value and turnover rate, allowing businesses to effectively prioritize their stock management efforts. The analysis classifies items into three categories:

- A Category: Items with high value and high demand. These typically comprise a small percentage of the total inventory but contribute significantly to revenue. They require close monitoring and efficient management to ensure availability and prevent stockouts.

- B Category: Items with moderate value and demand. These items are less critical than A-category items but still important for the business. They require regular monitoring and management to ensure adequate stock levels without tying up excessive capital.

- C Category: Items with low value and low demand. These items represent the bulk of the inventory but contribute less to overall revenue. They require minimal attention and can often be managed with simple replenishment strategies.

You can maximize efficiency and minimize costs by focusing resources on high-value, fast-moving items (A category) while optimizing inventory levels of slower-moving items (C category). Regularly reviewing and adjusting your ABC classifications ensures your inventory aligns with your business goals and market demand.

Related Read: ABC Analysis Report: A Guide to Maximizing Profitability

5. Establish Effective Supplier Relationships

Building strong relationships with your suppliers is key to successful wholesale inventory management. To ensure a steady supply of goods, negotiate favorable pricing and terms, collaborate on demand forecasting, and maintain open communication channels. By working closely with your suppliers, you can minimize lead times, reduce the risk of stockouts, and adapt quickly to changes in market demand.

6. Embrace Automation and Technology

Automation and technology play a vital role in streamlining wholesale inventory management processes. Implement barcode scanning, and other advanced technologies to enhance accuracy, efficiency, and visibility throughout your supply chain. By automating routine tasks and leveraging real-time data, you can minimize human error, improve inventory accuracy, and optimize stock levels to meet customer demand.

7. Monitor Key Performance Indicators (KPIs) Regularly

Regularly monitoring key performance indicators (KPIs) is essential for evaluating the effectiveness of your wholesale inventory management efforts. Track metrics such as inventory turnover, fill rate, and stockout frequency to identify areas for improvement and make informed decisions. By staying proactive and responsive to changes in market conditions, you can continuously optimize your stock management process and drive sustainable business growth.

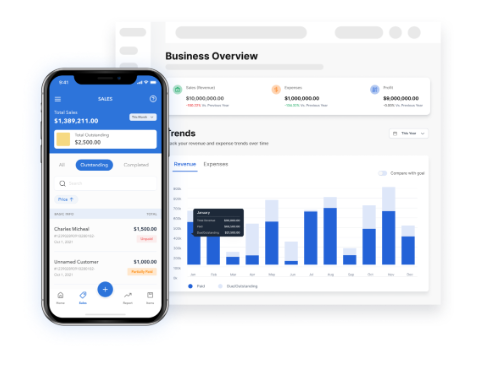

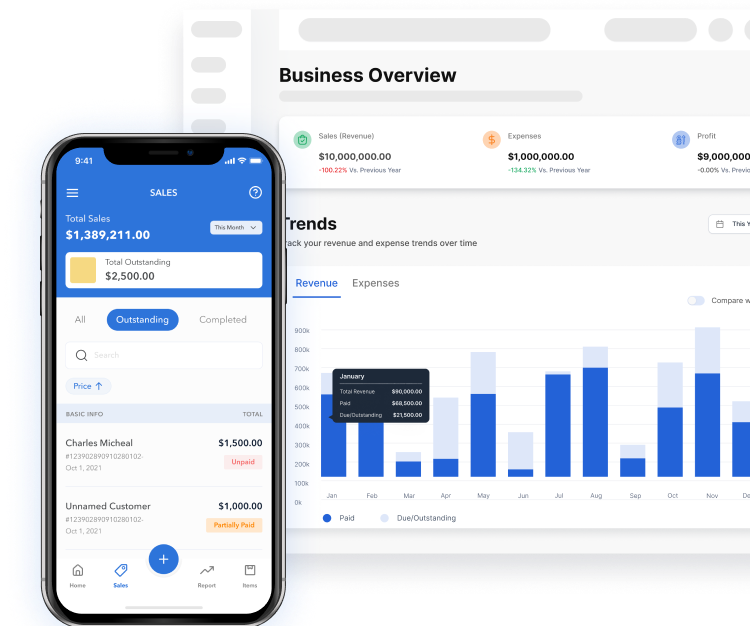

Manage Your Wholesale Inventory with Vencru

Vencru is a simple inventory management, invoicing, and accounting software designed for wholesale businesses of all sizes. With Vencru, experience robust wholesale inventory management featuring:

- Streamlined Inventory Management: Gain real-time insights into stock levels, receive alerts for low stock or expired items, and track products with barcode scanning—all within Vencru’s intuitive inventory management features.

- Efficient Purchase Order and Supplier Management: Generate purchase orders easily, convert them into bills, and manage supplier information effortlessly. Vencru’s purchase management tools help you stay on top of supplier relationships and metrics.

- Seamless Sales and Client Management: Record and manage client payments efficiently with Vencru’s invoicing and payment management features. Keep track of delivery statuses and outstanding balances to ensure smooth transactions.

- Expense Tracking: Record and monitor expenses to keep your wholesale business finances in order. Vencru provides insights into accounts payables, helping you stay on top of your financial obligations.

- Actionable Business Insights: Access over 15 insightful reports, including robust double-entry accounting reports like income statements, trial balances, and statements of financial position. These reports provide valuable insights into your business’s financial health, empowering you to make informed decisions.

Book a demo today or start a free trial to enjoy the simplest wholesale inventory management software.