Controlling inventory costs and assigning them correctly to projects is crucial for successful construction project management. Budgeting and billing accurately is essential for your business to ensure it stays profitable and sustainable in the long run. With multiple projects running simultaneously, each with its own materials, equipment, and labor costs, tracking expenses can become complex. However, modern technology and software like Vencru make monitoring and managing costs easier.

This article will discuss seven essential ways to track and assign inventory costs to projects. This helps with budgeting and billing, leading to business growth and success.

What is Inventory Cost?

Inventory cost refers to the total expense associated with storing, managing, and purchasing goods or materials for a business. In construction, inventory costs include raw materials like lumber and steel, and tools and equipment needed for project execution. These costs are pivotal as they directly impact construction projects’ overall budget and profitability.

Related Read: What Is Inventory in Accounting and How Is It Calculated?

Why is Accurate Budgeting and Billing Important?

Accurate budgeting and billing are fundamental for the success of any construction project. They ensure financial stability and cash flow, foster client trust, and enhance project management. Here’s why they are essential:

- Financial Control: Precise budgeting helps monitor expenses, avoid cost overruns, and ensure the project remains financially viable.

- Client Satisfaction: Transparent and accurate billing builds client trust and reduces disputes over charges, leading to stronger business relationships.

- Profit Margins: By monitoring costs closely, construction businesses can protect their profit margins and financial health. Thus ensuring the long-term success of their operations.

- Decision Making: Accurate financial data helps inform decisions about resource allocation, pricing, and future project planning.

Related Read: Capital Budgeting: Detailed Guide

7 Ways to Track and Allocate Inventory Costs to Specific Projects Effectively

- Establish a Job Costing System

- Implement Barcode Scanning and RFID Technology

- Create Project-Specific Purchase Orders

- Utilize Integrated Inventory and Project Management Software

- Track Time and Materials

- Apply Cost Codes

- Conduct Regular Inventory Counting

1. Establish a Job Costing System:

Implement a job costing system to track costs associated with each project accurately. While manual tracking on a spreadsheet is an option, it’s prone to errors. A job costing system tracks expenses for each project, helping to understand actual costs and manage budgets effectively.

Using software solutions like Vencru, rather than manual tracking, minimizes errors and streamlines the process. Vencru’s mobile app ensures accurate accounting for both stock and project-specific items.

2. Implement Barcode Scanning and RFID Technology:

Barcode scanning or RFID technology can automate the tracking of materials and equipment. Automating inventory tracking reduces manual entry errors and provides real-time data on inventory usage. This precise tracking is crucial for accurate cost allocation and helps prevent project delays due to inventory shortages. Software solutions like Vencru enable inventory tracking to be automated with barcode scanners.

Related Read: Vencru’s Barcode Scanner

3. Create Project-Specific Purchase Orders:

Generate purchase orders dedicated to each project to ensure direct cost allocation. Using separate purchase orders for each project makes it easier to track expenses and ensures ordering costs are assigned correctly. This practice also helps maintain accurate budgeting throughout the project’s lifecycle.

Related Read: Vencru’s Purchase Order Generator

4. Utilize Integrated Inventory and Project Management Software:

Opt for software that integrates inventory management with project management. This integration allows seamless material usage and cost tracking directly within project workflows, enhancing budget accuracy.

Related Read: Best inventory management systems

5. Track Time and Materials:

Monitoring workers’ time on specific tasks and the materials used is essential for accurately allocating labor and inventory costs to projects. This detailed tracking helps identify areas of over- or under-utilization and adjust budgets accordingly.

6. Apply Cost Codes:

Assign cost codes to different inventory items and project activities. Cost codes for inventory items and project activities simplify expense tracking and ensure accurate cost allocation. Cost codes aid in budget management and financial reporting and provide insights into project cost trends.

7. Conduct Regular Inventory Counting:

Regularly reconcile physical inventory counts with recorded levels. This helps identify and correct discrepancies, maintaining accurate cost allocation. Investigate and adjust any differences to maintain precise cost allocation and prevent budgeting errors. This also helps prevent carrying extra materials not needed, minimizing inventory holding costs and storage costs.

Related Read: Stock counting templates and more

Perform Inventory Tracking with Vencru

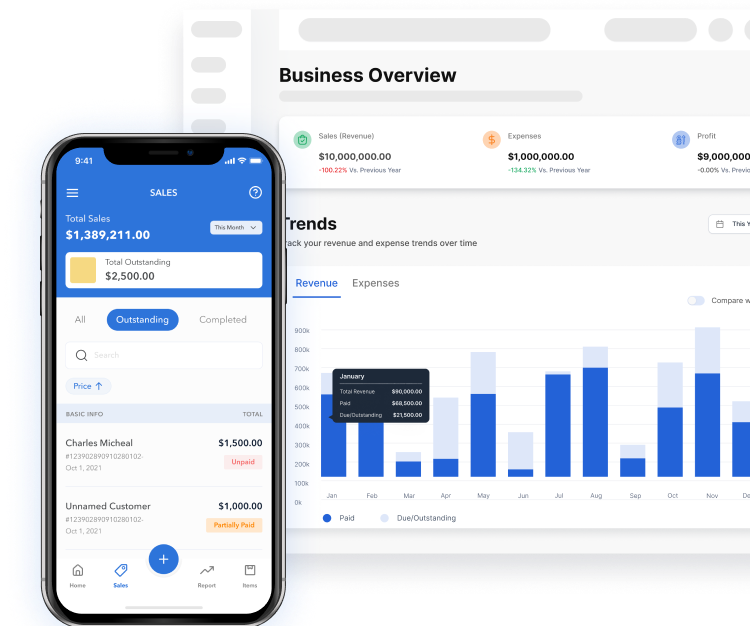

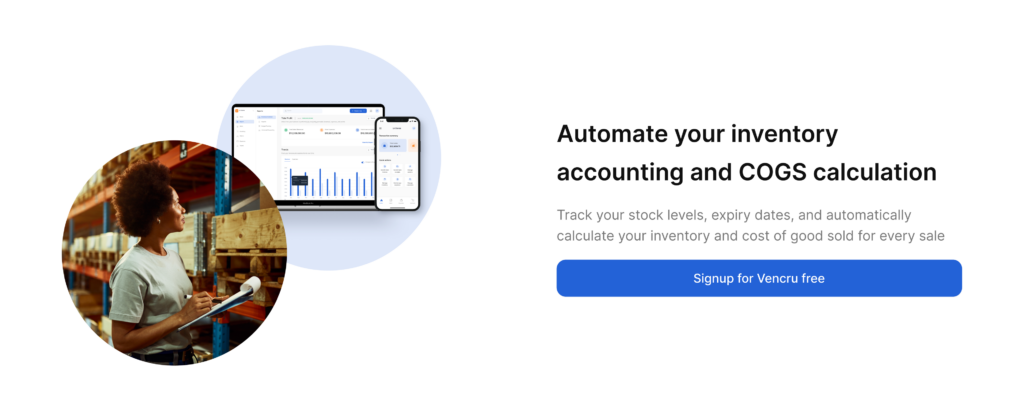

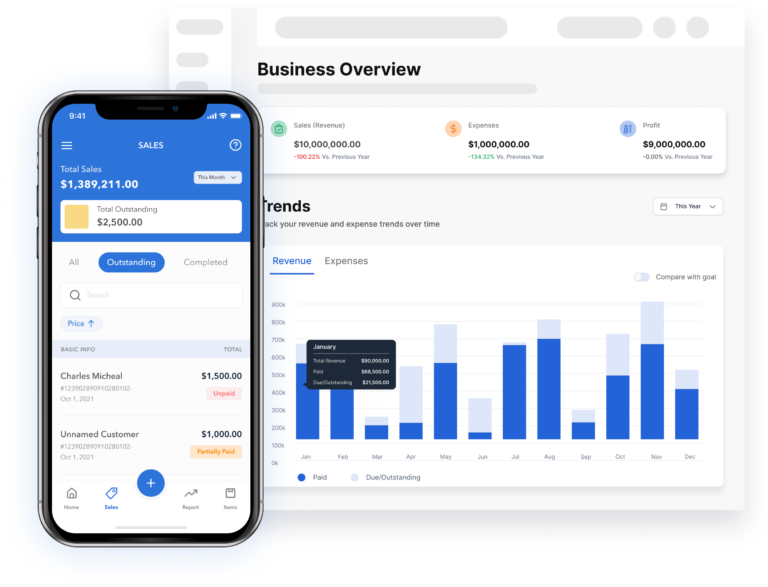

Vencru is a simple inventory management software designed to simplify tracking and allocating inventory costs for construction projects. Here’s how Vencru can enhance your budgeting and billing processes:

- Real-Time Inventory Management: Vencru provides real-time updates on inventory levels, ensuring you always have an accurate picture of available materials and equipment.

- Project-Specific Tracking: With Vencru, you can easily track inventory usage and costs for individual projects, enabling precise cost allocation and budgeting.

- Automated Reordering: Set up low stock alerts and automate reordering to prevent project delays due to material shortages.

- Built-in Accounting: Vencru includes accounting software for seamless financial management and reporting.

- Easy-to-use interface: The user-friendly design allows site managers and project teams to handle inventory effectively with minimal training required.

By leveraging Vencru for inventory tracking, construction businesses can ensure accurate budgeting and billing, improving the bottom line, client satisfaction, and overall project success.

Ready to learn more? Contact us to schedule a live demo and see how Vencru can help you track your project’s inventory and budget.