In today’s fast-paced business environment, barcode scanning has become an essential tool in effective inventory management. This innovative technology streamlines barcode management processes, enabling businesses to track their products with unparalleled accuracy and efficiency. By utilizing a barcode inventory system, companies can optimize their inventory control, minimize errors, and ensure timely order fulfillment.

In this blog, we will explore how barcode scanning works, how it optimizes inventory management, and why it’s a must-have solution for any business looking to improve its inventory processes. We’ll be discussing:

- How Does Barcode Scanning Work?

- 5 Ways to Optimize Your Inventory Management Using Barcode Scanning

- How to Implement Barcode Scanning

- Common Barcoding Challenges and Solutions

- Barcode Scanning vs. Other Inventory Management Technologies

How Does Barcode Scanning Work?

Barcode scanning is a technology that uses optical scanners to read printed barcodes on products and translate them into digital information. This process involves several key components:

- Barcode: A visual representation of data, typically a series of parallel lines or patterns that can be scanned and interpreted by a machine.

- Scanner: An optical device that reads the barcode by emitting a laser or LED light and capturing the reflected light patterns.

- Decoder: Software that translates the scanned barcode into readable data for the inventory management system.

- Inventory System: A digital system that stores and manages the scanned data, providing real-time updates and analytics.

The scanning process is simple yet powerful. When a barcode is scanned, the scanner reads the light patterns and sends the information to the decoder. The decoder translates these patterns into digital data, which is then stored in the inventory system. This automated process ensures accurate and instant data capture, minimizing errors and enhancing efficiency.

Related Read: Barcode Scanner App for Inventory Management

Types of Barcodes

There are various types of barcodes used in different industries, each serving specific purposes. The most common types include:

- UPC (Universal Product Code): Widely used in retail for tracking trade items. It consists of 12 numerical digits.

- EAN (European Article Number): Similar to UPC but used internationally. It can have 8 or 13 digits.

- Code 39: Used in non-retail settings, such as logistics and healthcare. It can encode both letters and numbers.

- QR Code (Quick Response Code): A two-dimensional barcode that can store large amounts of data, including URLs and text. It’s widely used in marketing and mobile applications.

- Data Matrix: Another two-dimensional barcode used in manufacturing and aerospace for marking small items due to its ability to store more data in a smaller space.

5 Ways to Optimize Your Inventory Using Barcode Scanning

Barcode scanning transforms inventory management by automating the data capture process, leading to improved accuracy, speed, and overall efficiency. This technology not only streamlines inventory processes but also provides real-time data, which is crucial for making informed business decisions. Let’s delve into five key ways to optimize your inventory management using barcode scanning.

1. Enhancing Accuracy and Reducing Errors

Manual data entry often leads to human errors, which can create mistakes in inventory records and disrupt business operations. By implementing a barcode inventory system, businesses can significantly enhance accuracy and minimize these errors through automated data capture. This approach not only ensures precision by reducing human error but also maintains consistency across all inventory items. As a result, it fosters reliability in inventory management, significantly decreasing the risk of costly mistakes and discrepancies.

2. Increasing Efficiency and Speed

Barcode scanning significantly enhances the inventory management process, enabling businesses to manage large volumes of inventory swiftly and effectively. By scanning barcodes instead of manually entering each item, employees can instantly update the inventory system.

The key benefits of this technology include time savings by speeding up tasks like stocktaking and order fulfillment, increased labor efficiency by freeing up employees for higher-value responsibilities, and quick updates that provide real-time inventory information for better decision-making.

3. Improving Inventory Tracking and Visibility

By implementing barcode scanning, businesses achieve real-time visibility into their inventory levels, as each scan updates the inventory system instantly. This provides accurate information on stock levels, item locations, and movement history, enabling businesses to track inventory more effectively and maintain the right products in the right quantities. The key benefits of this system include real-time tracking for immediate updates on inventory status and enhanced security that minimizes the risk of theft and loss.

4. Streamlining the Supply Chain

Barcode scanning enables seamless integration with various business systems, including point-of-sale (POS), enterprise resource planning (ERP), and warehouse management systems (WMS). This integration promotes smooth data flow across departments, streamlining the supply chain and enhancing coordination.

This approach brings key benefits, such as integrated systems that facilitate smooth communication between different business platforms, increased supply chain efficiency by reducing delays and enhancing coordination, and automated processes that simplify essential tasks like receiving, shipping, and restocking inventory.

5. Enhancing Customer Satisfaction

Effective inventory management plays a crucial role in boosting customer satisfaction. By implementing barcode scanning, businesses can maintain reliable stock levels, ensuring that the right products are always available and significantly reducing the risk of stockouts and backorders. This leads to faster order fulfillment and precise order processing, ultimately enhancing the customer experience and fostering greater loyalty.

Additionally, the speed of order fulfillment is greatly improved, leading to quicker processing times. This overall efficiency not only enhances service quality but also increases accuracy in order picking and shipping, resulting in a better experience for customers.

How to Implement Barcode Scanning

- Assess Your Needs: Determine the volume of inventory and specific requirements for your business. Consider factors such as inventory size, complexity, and the need for real-time updates.

- Choose the Right Equipment: Select barcode scanners and software that suit your business needs. Options range from handheld scanners to mobile devices and integrated systems.

- Integrate with Existing Systems: Ensure that your barcode scanning solution integrates seamlessly with your existing business systems, such as ERP, POS, and WMS.

- Train Your Staff: Provide training for your employees on how to use barcode scanners effectively. This includes understanding the software, handling the devices, and troubleshooting common issues.

- Test and Optimize: Conduct thorough testing to ensure that the barcode scanning system works as expected. Make adjustments as needed to optimize performance and efficiency.

Common Barcoding Challenges and Solutions

Initial Investment Costs

While the initial investment in barcode scanning technology can be high, the long-term benefits and cost savings often outweigh the initial costs. Consider scalable solutions like Vencru that offer flexible pricing plans to manage expenses.

Training and Adoption

Ensure comprehensive training for employees and choose user-friendly systems. Vencru’s intuitive interface minimizes training time and enhances user adoption.

Integration with Existing Systems

Select barcode scanning solutions that are compatible with your current business systems. Vencru offers seamless integration with ERP, POS, and WMS systems, ensuring smooth data flow across your organization.

Future Trends in Barcode Technology

- RFID Technology: Radio-frequency identification (RFID) offers greater data storage capacity and faster scanning capabilities compared to traditional barcodes.

- AI and Machine Learning: These technologies can predict inventory needs, optimize stock levels, and identify patterns in inventory data.

- IoT Integration: The Internet of Things (IoT) allows real-time tracking and monitoring of inventory items, enhancing visibility and control.

- Blockchain: Blockchain technology provides secure, transparent, and tamper-proof records of inventory transactions.

Barcode Scanning vs. Other Inventory Management Technologies

| Inventory Management Technology | Pros | Cons |

|---|---|---|

| Barcode Scanning | – Cost-effective setup | – Initial setup costs |

| – Simple to use and implement | – Dependency on technology | |

| – Reliable accuracy and efficiency | ||

| – Fast scanning speeds | ||

| – Real-time inventory tracking | ||

| – Reduces stockouts and improves order fulfillment | ||

| RFID | – Fast scanning; can read multiple tags simultaneously | – Higher initial costs |

| – Stores more data | – More complex infrastructure needed | |

| – Reduces manual work | ||

| Manual Data Entry | – Low initial cost | – Time-consuming and labor-intensive |

| – Simple implementation | – High error rates and not scalable | |

| – Requires specialized knowledge | ||

| Automated Inventory Systems | – High efficiency and accuracy | – High setup and maintenance costs |

| – Integrates well with various technologies | – Can be complex to implement | |

| – Provides advanced analytics |

Related Read: Barcode Scanning vs. Manual Data Entry

Leveraging Vencru for Optimized Inventory Management

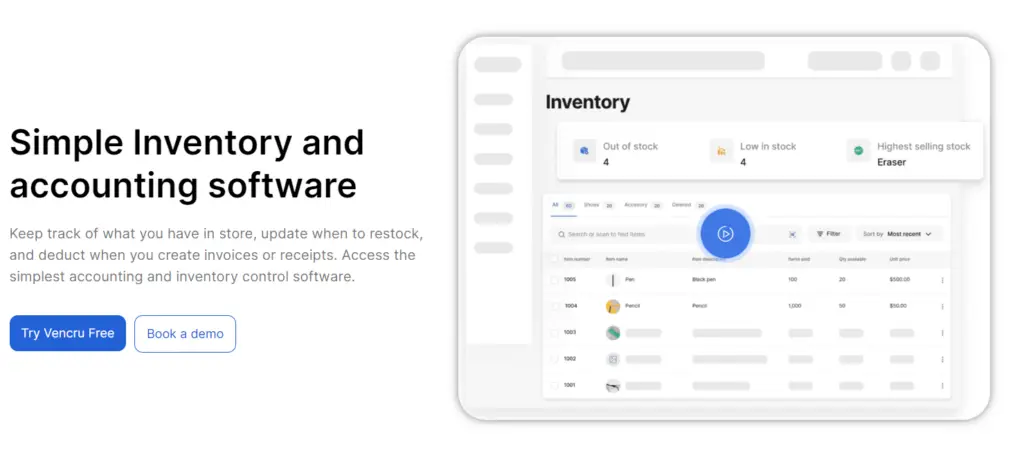

Vencru provides a comprehensive solution for businesses looking to streamline their inventory management processes. By integrating barcode scanning capabilities, Vencru enhances accuracy, efficiency, and overall control over inventory. Here’s how Vencru can transform your inventory management:

- Seamless Integration: Vencru’s barcode scanning technology integrates effortlessly with your existing systems, ensuring a smooth transition and minimal disruption to your operations.

- Real-Time Updates: With Vencru, each scan updates your inventory system in real time, providing accurate and up-to-date information on stock levels and item locations.

- Error Reduction: Automate data capture with Vencru’s barcode inventory system to minimize human errors and discrepancies, ensuring reliable inventory records.

- Increased Efficiency: Vencru’s barcode scanning accelerates inventory processes, allowing your team to handle large volumes quickly and focus on higher-value tasks.

- Cost Savings: By reducing manual data entry and errors, Vencru helps lower labor costs and potential expenses associated with inventory discrepancies.

Conclusion

Unlocking the power of barcode scanning can transform your inventory management processes. By enhancing accuracy, increasing efficiency, improving tracking, streamlining the supply chain, and boosting customer satisfaction, barcode scanning offers numerous benefits that can transform your business operations. Vencru provides the tools and support you need to implement barcode scanning effectively, ensuring that your inventory management is optimized for success. Embrace the future of inventory management with Vencru and stay ahead in today’s competitive market.

Start using Vencru here or book a demo to unlock the power of barcode scanning and enhance your inventory management.

Related Content