Choosing between Just-in-Time and Just-in-Case inventory strategies depends on your business needs, supply chain reliability, and cost considerations. Each approach offers distinct advantages and challenges. The right strategy can optimize your inventory management and boost overall business performance. By leveraging advanced inventory management solutions like Vencru, you can enhance the efficiency and accuracy of your chosen strategy, keeping your business competitive and responsive to market demands. In this blog, we’ll be discussing:

- What is JIT Inventory?

- What is JIC Inventory?

- Choosing the right strategy for your business

- Enhancing your Inventory Management with Vencru

What is Just-in-Time (JIT) Inventory?

Just-in-time (JIT) inventory is an inventory strategy that minimizes the amount of inventory a business holds by aligning the ordering and production of goods with actual customer demand. Instead of keeping large quantities of stock on hand, JIT ensures that materials and products are received or produced just before they are needed. This approach reduces holding costs, minimizes waste, and improves overall operational efficiency by avoiding overproduction and excess inventory.

Features of JIT:

- Minimal Inventory Levels: Keep inventory levels low by implementing a just-in-time system, where stock arrives precisely when needed for production or sale. This approach minimizes storage costs and reduces the risk of inventory obsolescence, freeing up cash flow for other business needs.

- Demand-Driven: Align production schedules closely with real-time customer demand, reducing the likelihood of excess inventory and overproduction. By responding quickly to market fluctuations, businesses can optimize inventory turnover and meet customer needs more effectively.

- Supplier Coordination: Build strong, collaborative relationships with reliable suppliers to ensure timely and consistent deliveries. Regular communication and contingency planning with suppliers can help avoid delays and maintain a steady supply chain, even during disruptions.

- Efficiency Focus: Streamline operations by eliminating waste and improving process efficiency at every stage of production. Implement lean manufacturing principles and continuous improvement strategies to enhance productivity, reduce lead times, and lower overall operational costs..

Advantages of JIT

Reduced Holding Costs

One of the primary benefits of JIT is the significant reduction in holding costs. With lower inventory levels, businesses have less capital tied up in stock, which leads to decreased expenses related to storage, insurance, and handling.

Minimized Waste

JIT focuses on producing only what is needed, exactly when it is needed. This approach minimizes waste by preventing overproduction and reducing the likelihood of obsolete inventory. Companies can optimize resource usage, leading to a more efficient production process and a lower environmental impact.

Improved Cash Flow

By keeping inventory levels low, JIT frees up cash that would otherwise be spent on purchasing and storing excess stock. This improved cash flow allows businesses to invest in growth opportunities, manage operational expenses more effectively, and maintain better liquidity.

Flexibility

JIT provides companies with the ability to respond to changes in customer demand quickly. This flexibility gives businesses a competitive edge, as they can adapt their production schedules to meet market needs without being burdened by large inventories of unsold goods.

Disadvantages of JIT

Supply Chain Dependence

JIT heavily relies on a highly efficient and reliable supply chain. Any disruption in the supply chain, such as delays in deliveries, strikes, or natural disasters, can halt production and lead to stockouts. This dependence on timely supplies can make businesses vulnerable to unforeseen disruptions.

Increased Coordination

Implementing JIT requires meticulous planning and coordination between suppliers, production teams, and other stakeholders. This increased need for coordination demands sophisticated management systems and strong communication channels.

Limited Buffer Stock

JIT operates with minimal buffer stock, meaning there is little to no excess inventory available to meet unexpected spikes in demand. This lack of safety stock can result in missed sales opportunities if customer demand suddenly increases.

What is Just-in-Case (JIC) Inventory?

Just-in-case inventory refers to a strategy where businesses keep higher inventory levels as a precaution against potential uncertainties in demand and supply chain disruptions. This approach ensures that products are available to meet customer needs even if unexpected issues arise in the supply chain or if demand exceeds forecasts. By maintaining extra stock, companies aim to avoid stockouts and maintain a steady flow of products, although this can lead to higher holding costs and increased risk of excess inventory.

Features of JIC

- Buffer Stock: JIC inventory management involves maintaining additional stock levels beyond immediate needs to handle unforeseen demand spikes or supply chain disruptions. This buffer stock acts as a safety net, ensuring that there is always an extra inventory available to meet customer demands or manage unexpected delays in supply.

- Risk Mitigation: By keeping extra inventory on hand, JIC helps in mitigating risks associated with stockouts and supply chain interruptions. It provides a safety cushion that helps businesses avoid the negative consequences of not having enough stock to meet demand.

- Predictive Ordering: This involves ordering inventory based on forecasts, historical data, and anticipated future needs. This predictive approach aims to estimate the right amount of inventory to hold, balancing the need to avoid stockouts with the cost of maintaining excess stock.

Advantages of JIC

Reduced Risk of Stockouts

One of the main advantages of JIC is its ability to ensure that customer orders can always be fulfilled. By maintaining sufficient inventory levels, businesses can prevent stockouts, which enhances customer satisfaction and loyalty.

Supply Chain Resilience

The buffer stock maintained under this strategy enhances supply chain resilience by providing a safeguard against disruptions. Having extra inventory in reserve ensures that operations continue smoothly without major interruptions.

Stable Production

Production lines can operate smoothly without the constant need to adjust to fluctuating inventory levels. The availability of buffer stock ensures that delays in material supply or sudden changes in demand do not disrupt production schedules.

Disadvantages of JIC

Higher Holding Costs

Maintaining buffer stock results in higher holding costs due to increased storage requirements and capital tied up in inventory. Businesses need to invest in warehouse space, insurance, and other storage-related expenses.

Risk of Obsolescence

Excess inventory can become obsolete, particularly in industries characterized by rapid technological changes or shifting consumer preferences. If products remain unsold for too long, they may lose their value or relevance, leading to financial losses.

Increased Waste

Higher inventory levels can lead to increased waste if products are not sold in time. Excess stock that exceeds demand can result in spoilage, damage, or expiration, especially for perishable goods.

Choosing the Right Strategy for Your Business

Deciding between JIT and JIC inventory strategies depends on several factors:

- Demand Predictability: Use JIT if your market demand is predictable. For unpredictable or seasonal demand, JIC provides the necessary buffer.

- Supply Chain Reliability: JIT requires a reliable supply chain with consistent delivery times. If your supply chain is prone to disruptions, JIC can help mitigate risks.

- Cost Considerations: Evaluate holding costs versus potential stockout costs. JIT reduces holding costs, while JIC prevents lost sales.

- Production and Storage Capacity: Consider your production capabilities and storage space. JIT is ideal for limited storage, while JIC suits businesses with ample space and production flexibility.

- Technology and Systems: Advanced inventory management systems like Vencru manage both strategies effectively with real-time tracking, automated reordering, and comprehensive reporting.

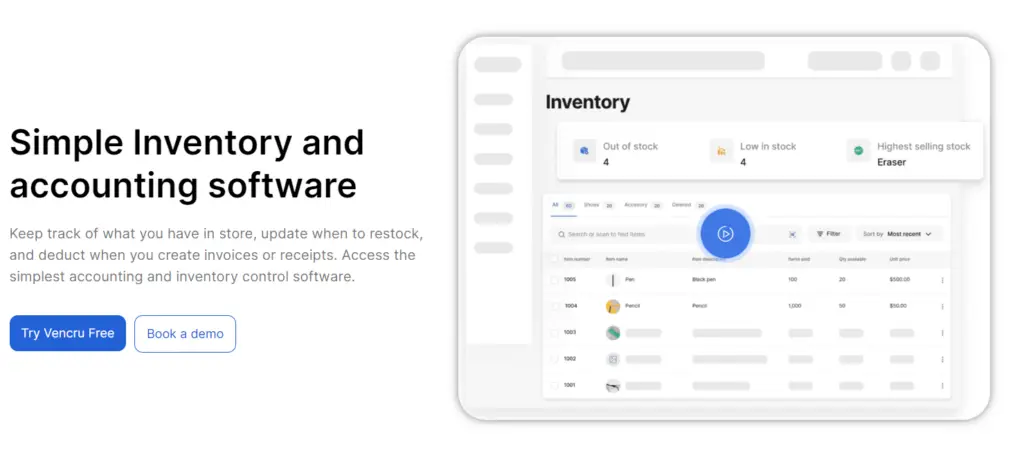

Enhancing Your Inventory Management with Vencru

No matter which inventory strategy you choose, Vencru’s inventory management solution can enhance your efficiency and accuracy:

- Real-Time Inventory Tracking: Vencru provides real-time updates on inventory levels, ensuring accurate and up-to-date information for both strategies.

- Automated Reordering: Vencru’s automated reordering actively ensures timely replenishment, reducing the risk of stockouts or overstocking and this helps optimize your inventory.

- Comprehensive Reporting: Generate detailed reports on inventory movements, demand trends, and supplier performance for informed decision-making.

- Seamless Integration: Vencru integrates seamlessly with other business systems for smooth operations and accurate forecasts.

- User-Friendly Interface: Vencru’s intuitive interface simplifies inventory management, tracking stock movements, and accessing critical data.

Conclusion

Choosing between both inventory strategies depends on your business needs, supply chain reliability, and cost considerations. Each approach offers distinct advantages and challenges. The right strategy can optimize your inventory management and boost overall business performance. By leveraging advanced inventory management solutions like Vencru, you can enhance the efficiency and accuracy of your chosen strategy, keeping your business competitive and responsive to market demands.

Related Content