Accurate demand forecasting is vital for effective inventory management. It ensures that businesses can meet customer demand without overstocking or understocking, optimizing inventory levels and boosting profits. In this blog, we’ll explore what demand forecasting is, various methods and real-world examples, its impact on inventory management, and best practices, and conclude with key takeaways. We’ll be discussing:

- What is Demand Forecasting?

- Methods of Demand Forecasting?

- How Demand Forecasting Affects Inventory Management

- Best Practices for Demand Forecasting in Inventory Management

- Benefits of Accurate Forecasting

What is Demand Forecasting?

Demand forecasting is the process of predicting future customer demand for a product or service over a specific period. It involves analyzing historical sales data, market trends, and other relevant factors to estimate the quantity of goods that customers will purchase in the future. By understanding these patterns, businesses can make informed decisions about production, inventory, and supply chain management.

Accurate forecasting helps companies optimize inventory levels with actual market demand, reducing the risk of stockouts and excess inventory. It also aids in financial planning, budgeting, and enhancing customer satisfaction by ensuring that products are available when needed.

Methods of Demand Forecasting

There are several methods used in inventory forecasting, each with its strengths and applications. Here are some of the most common techniques:

Qualitative Methods

Qualitative methods rely on expert opinions and market research to predict future demand. These techniques are particularly useful when historical data is limited or when launching new products.

- Delphi Method: A panel of experts provides estimates and assumptions about future demand. Through a series of rounds, their forecasts are refined until a consensus is reached.

- Market Research: Surveys, interviews, and focus groups gather information directly from customers, providing insights into future purchasing behavior and preferences.

- Executive Judgment: Experienced executives and managers use their knowledge and intuition to predict demand based on market conditions and internal business factors.

Quantitative Methods

Quantitative methods use historical data and statistical techniques to generate demand forecasts. These methods are often more objective and accurate than qualitative methods.

- Time Series Analysis: This demand forecasting method analyzes historical data to identify patterns and trends that can be projected into the future. Common techniques include moving averages, exponential smoothing, and ARIMA models.

- Causal Models: These models examine the relationship between demand and other variables, such as price, economic indicators, and marketing efforts. Regression analysis is a popular technique used in causal modeling.

- Simulation Models: These models use computer algorithms to simulate various scenarios and predict demand based on different assumptions and variables.

Hybrid Methods

Hybrid methods combine qualitative and quantitative approaches to leverage the strengths of both demand forecasting methods. For example, a company might use time series analysis to generate a baseline forecast and then adjust it based on expert opinions or market research findings.

How Demand Forecasting Affects Inventory Management

Accurate forecasting has a significant impact on inventory management. Here are some key ways it influences business operations:

Optimized Inventory Levels

By accurately predicting future demand, businesses can maintain optimal inventory levels, ensuring that they have enough stock to meet customer needs without overstocking. This reduces carrying costs, minimizes the risk of obsolescence, and improves cash flow.

Reduced Stockouts

Forecasting helps businesses anticipate demand spikes and plan inventory accordingly. This reduces the likelihood of stockouts, ensuring that products are available when customers need them and enhancing customer satisfaction.

Improved Production Planning

Accurate demand forecasts enable manufacturers to plan production schedules more effectively, balancing production capacity with customer demand. This reduces lead times, minimizes production bottlenecks, and enhances efficiency.

Enhanced Supply Chain Management

Stock forecasting provides valuable insights for supply chain management, helping businesses align procurement, production, and distribution activities with predicted demand. This improves coordination, reduces lead times, and lowers overall supply chain costs.

Better Financial Planning

Demand forecasting aids in financial planning and budgeting by providing accurate estimates of future sales and revenue. This helps businesses allocate resources more effectively, plan investments, and manage working capital.

Strategic Decision Making

Accurate demand forecasts support strategic decision-making by providing insights into market trends, customer preferences, and competitive dynamics. This enables businesses to make informed decisions about product launches, pricing strategies, and market expansion.

Best Practices for Demand Forecasting in Inventory Management

Implementing best practices in demand forecasting can significantly enhance its accuracy and effectiveness. Here are some key recommendations:

Use Multiple Forecasting Methods

Combining different forecasting methods can provide more accurate and reliable results. For example, using both time series analysis and causal models can help capture different aspects of demand patterns and improve forecast accuracy.

Regularly Update Forecasts

Demand forecasting is not a one-time activity. Regularly updating forecasts with the latest data ensures that predictions remain accurate and relevant. This helps businesses respond quickly to changing market conditions and customer demand.

Incorporate External Data

Including external data, such as economic indicators, market trends, and competitor actions, can enhance the accuracy of demand forecasts. This provides a broader perspective and helps businesses anticipate changes in demand more effectively.

Collaborate Across Departments

Effective demand forecasting requires collaboration across different departments, including sales, marketing, finance, and supply chain. Sharing information and insights helps create a comprehensive view of demand and improves forecast accuracy.

Leverage Technology

Advanced forecasting tools and software can automate data analysis, improve accuracy, and streamline the forecasting process. Leveraging technology helps businesses save time, reduce errors, and make more informed decisions.

Monitor and Adjust

Continuous monitoring and adjustment of demand forecasts based on actual sales data and market feedback are crucial. This helps businesses identify discrepancies, refine their forecasting models, and improve accuracy over time.

Train and Develop Staff

Investing in training and development for staff involved in demand forecasting can enhance their skills and expertise. This ensures that they can effectively analyze data, use forecasting tools, and make informed decisions.

Related Read: Inventory Management Best Practices

Benefits of Accurate Demand Forecasting

Accurate demand forecasting is crucial for efficient inventory management, offering a range of benefits that enhance business operations and customer satisfaction.

1. Reduced Stockouts and Overstocks: Precise inventory forecasting helps maintain optimal stock levels, preventing stockouts that lead to lost sales. It also avoids overstocking, which can tie up capital and increase storage costs.

2. Improved Cash Flow: With accurate forecasts, businesses can better manage their inventory investments. This reduces the amount of capital tied up in excess stock and improves cash flow, allowing for better allocation of resources to other critical areas like marketing and product development.

3. Enhanced Customer Satisfaction: Meeting customer demand promptly is key to maintaining high levels of satisfaction. Accurate forecasting ensures popular items are always in stock, reducing wait times and backorders, thus improving the overall shopping experience and building customer loyalty.

4. Optimized Supply Chain Operations: Forecasting helps in planning and coordinating with suppliers more effectively. Businesses can place orders based on predicted demand, ensuring timely restocking and minimizing lead times. This smooth supply chain operation reduces the risk of delays and disruptions.

5. Lower Inventory Holding Costs: By avoiding overstocking, companies can significantly reduce costs associated with storing excess inventory, such as warehousing, insurance, and potential obsolescence. Accurate forecasting minimizes these expenses, contributing to overall cost savings.

6. Better Decision-Making: Accurate demand forecasts provide valuable insights into sales trends and customer behavior, enabling better decision-making regarding product assortment, pricing strategies, and market expansion. This data-driven approach helps businesses stay competitive and responsive to market changes.

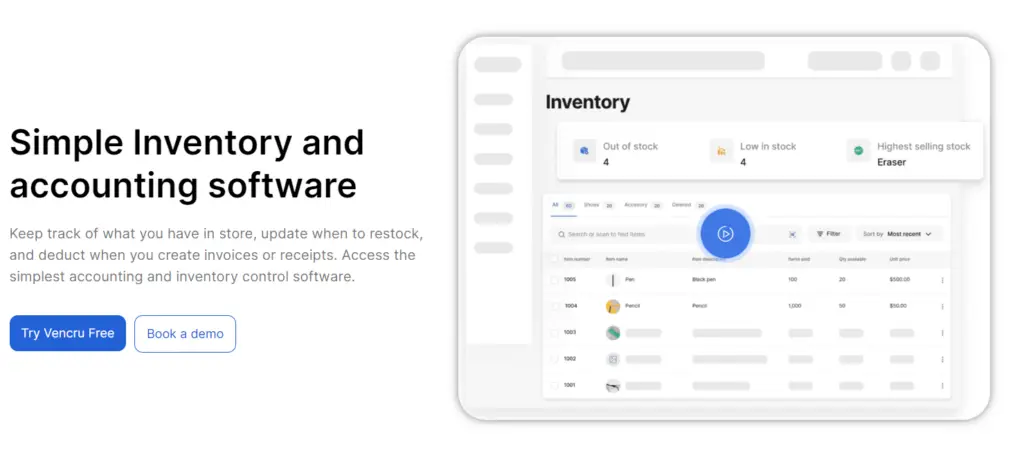

Simplify Demand Forecasting with Vencru

Accurate demand forecasting is essential for effective inventory management, and Vencru makes it straightforward. Here’s how:

- Automated Forecasting: Vencru utilizes historical sales data to generate precise demand forecasts, reducing guesswork and saving you time.

- Real-Time Insights: Access up-to-date inventory levels and sales trends, allowing you to adjust forecasts based on current market conditions.

- Comprehensive Analytics: Generate reports highlighting demand patterns, helping you make informed stock levels and purchasing decisions.

- Seamless Integration: Connect Vencru with your existing accounting systems for streamlined data flow and reporting.

- User-Friendly Interface: Vencru’s intuitive platform simplifies the forecasting process, ensuring you can quickly adapt to changes in demand.

Conclusion

Accurate demand forecasting is a cornerstone of effective inventory management. It enables businesses to maintain optimal inventory levels, reduce stockouts, improve production planning, enhance supply chain management, and support strategic decision-making. By implementing best practices and leveraging advanced forecasting methods, businesses can optimize their inventory management processes and boost overall performance. As market conditions and customer demands continue to evolve, the importance of accurate demand forecasting in inventory management will only grow, making it an essential capability for businesses aiming to stay competitive and responsive in today’s dynamic market.

Related Content