Effective inventory management is key to running a smooth and efficient business. To achieve this, one crucial component to understand is what PAR levels are and how to calculate them. Specifically, PAR stock helps businesses maintain the right amount of stock, ensuring they meet demand without overstocking or running out. In this blog, we will explore the role of PAR levels in inventory management. Furthermore, we will examine how these levels are used and outline their numerous benefits.

- What is PAR Level?

- How PAR Levels are Used in Inventory Management

- Benefits of Using PAR Levels in Inventory Management

- Difference Between PAR Level and a Reorder Point

- How Do You Calculate PAR Inventory Levels?

- What is PAR Level in Pharmacy?

What is PAR Level?

PAR stands for “Periodic Automatic Replacement Level.” PAR level or PAR Stock represents the minimum stock a business needs to keep operations running smoothly and meet customer demand. Setting these levels helps businesses avoid stockouts and overstocking, which can tie up capital and storage space.

Understanding PAR stock is crucial for balancing inventory. Enough stock meets demand without holding excess, which can increase costs and risk obsolescence. Insufficient stock can lead to lost sales and unhappy customers.

How PAR Levels are Used in Inventory Management

PAR levels play a crucial role in inventory management by helping businesses maintain a balance between adequate stock levels and avoiding excess. Here’s how businesses use PAR stock effectively:

- Reordering: When inventory levels fall below the PAR level, a reorder is triggered. This automatic process helps ensure that stock is replenished before it runs out, preventing stockouts and maintaining operational continuity.

- Inventory Planning: PAR levels provide a clear benchmark for how much stock is necessary to maintain efficient operations. This benchmark aids in planning inventory purchases and adjustments, ensuring that stock levels align with business needs.

- Cost Management: Maintaining optimal stock levels through PAR stock helps manage storage costs. This approach reduces the risk of inventory becoming obsolete, leading to better cost control and financial efficiency.

- Demand Fulfillment: Ensuring inventory does not drop below PAR stock guarantees that customer demand is consistently met. This practice improves service levels and customer satisfaction, contributing to a positive business reputation.

Related Read: What is Inventory Tracking? Methods and Systems

How to Set Optimum Stock Levels with Inventory Management Software

Setting the right stock levels can be challenging, but inventory management software simplifies this process significantly. Here’s how this technology can assist in setting optimum stock levels:

- Data-Driven Insights: Inventory management software provides detailed reports and analytics on historical sales, seasonality, and market trends. These insights allow you to set accurate stock levels tailored to your business needs, improving inventory accuracy.

- Automated Reordering: The software automates the reordering process based on your set PAR levels. This automation ensures timely stock replenishment, reduces manual intervention, and helps prevent stockouts.

- Real-Time Tracking: Real-time tracking allows you to monitor inventory levels continuously. This capability enables you to adjust PAR stock based on current demand and stock levels, ensuring your inventory remains optimal.

- Demand Forecasting: Predictive analytics in inventory management software helps forecast future demand. By using these forecasts, you can adjust PAR levels proactively to maintain optimal stock levels and respond to changes in demand.

- Integration: Integration with other business systems ensures consistency and accuracy across operations. By linking inventory management software with accounting, sales, and supply chain systems, you streamline your inventory processes and enhance overall efficiency.

Benefits of Using PAR Levels in Inventory Management

Implement PAR levels in your inventory management system to gain numerous advantages:

- Improve Inventory Control: Maintain optimal stock levels with PAR levels, reducing the risk of stockouts and overstocking. This ensures you always have the right amount of inventory on hand.

- Enhance Customer Satisfaction: Ensure products are consistently available, improving service levels and customer satisfaction. Meet customer demand promptly to build trust and foster loyalty.

- Increase Cost Efficiency: Prevent overstocking to reduce holding costs and minimize the risk of inventory becoming obsolete. This enhances overall financial management.

- Boost Operational Efficiency: Streamline the reordering process and reduce manual inventory checks to save time and resources. This leads to smoother day-to-day operations.

- Improve Cash Flow: Avoid excess inventory to free up capital for other investments. This improved cash flow allows businesses to allocate resources more effectively and support growth initiatives.

Difference Between PAR Level and a Reorder Point

Periodic Automatic Replacement levels and reorder points are related concepts but serve different purposes:

- PAR Level: Refers to the minimum quantity of inventory that must be maintained at all times. When inventory falls below this level, it signals the need for reordering.

- Reorder Point: The specific inventory level at which a new order should be placed to prevent stock from reaching the PAR level. It is calculated based on lead time and average daily usage.

In essence, while the reorder point helps trigger the reordering process, the PAR stock sets the minimum threshold to ensure inventory availability. Understanding both concepts helps businesses manage inventory more effectively and avoid common pitfalls.

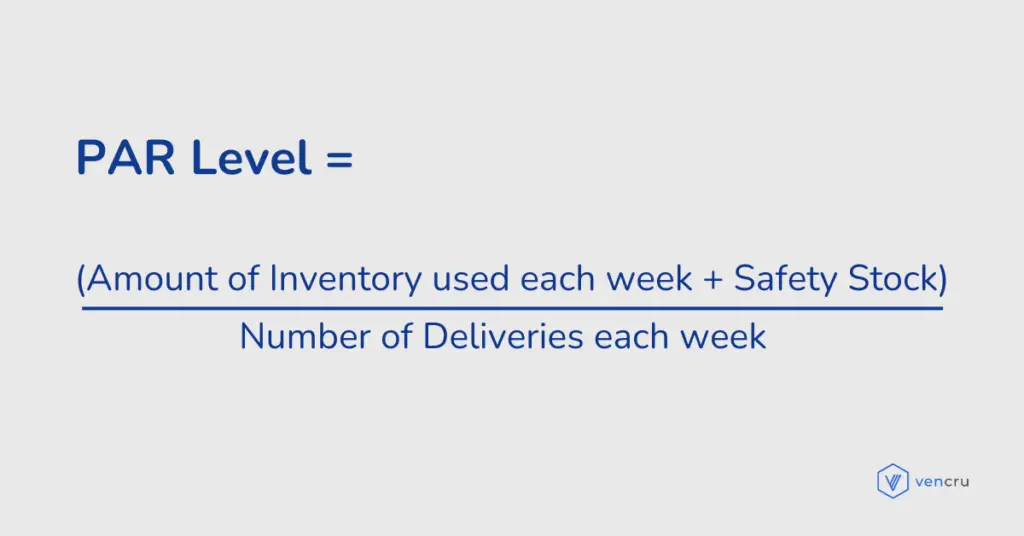

How Do You Calculate PAR Inventory Levels?

To calculate PAR levels accurately, follow these steps:

- Determine the usage rate: Analyze historical sales data to calculate the average daily or weekly usage of the product. This provides a solid foundation for setting appropriate PAR levels.

- Account for lead time: Consider the time it takes for an order to be fulfilled. Make sure that inventory levels are sufficient to cover demand during this period to prevent stockouts.

- Calculate safety stock: Establish the right amount of safety stock by evaluating factors such as demand variability, lead time reliability, and the desired service level.

- Apply the PAR level formula: Use the formula to compute the optimal stock level based on your analysis and calculations.

- Adjust for seasonality: Modify the PAR stock to accommodate seasonal demand variations. This adjustment ensures that inventory levels are suitable throughout the year.

Example:

Consider a pharmacy that uses 700 units of a particular medication per week. They receive deliveries twice a week and maintain a safety stock of 300 units.

- Amount of Inventory Used Each Week: 700 units

- Safety Stock: 300 units

- Deliveries per week: 2

Using the PAR level formula:

(700 units + 300 units) / 2 = 500 units

Therefore, the pharmacy should aim to have 500 units of the medication in stock after each delivery.

What is PAR Level in Pharmacy?

In pharmacies, PAR levels are crucial for managing medication inventory effectively. Here’s how they are applied:

Firstly, ensuring availability is key. Pharmacies utilize PAR stock to guarantee that essential medications are consistently in stock. This approach meets patient needs reliably and prevents shortages.

Furthermore, maintaining appropriate stock levels aids in regulatory compliance. It helps pharmacies adhere to regulations and avoid running out of critical medications, ensuring they meet legal and safety standards.

Moreover, PAR levels play a significant role in managing expiry dates. By monitoring inventory with medication expiry in mind, pharmacies can reduce waste and ensure that medications are used before expiration.

Finally, optimizing space is another benefit. Effective use of PAR stock allows pharmacies to manage shelf space efficiently. By keeping high-demand medications readily accessible and reducing clutter, pharmacies enhance operational efficiency

Related Read: Chart of Accounts for Healthcare Industry

Streamline Your Inventory Management with Vencru

For a more efficient approach to inventory management and optimizing PAR levels, use Vencru. Vencru’s inventory management software provides advanced features like real-time tracking, automated reordering, and detailed analytics. Integrate Vencru into your operations to maintain optimal stock levels, enhance demand forecasting, and streamline your inventory processes.

Conclusion

Understanding how to calculate and implement PAR levels is crucial for effective inventory management. Consequently, maintaining optimal stock levels ensures businesses can meet customer demand, manage costs, and improve operational efficiency. Furthermore, by leveraging the right tools and strategies, such as inventory management software, businesses can streamline their inventory processes and avoid common issues related to stock management.

For those looking to enhance their inventory management further, exploring solutions like Vencru can provide the tools needed to stay ahead and ensure smooth operations. Moreover, by integrating advanced inventory management solutions, businesses can achieve greater efficiency and maintain optimal stock levels.

Related Content