Inventory management is the systematic approach to sourcing, storing, and selling inventory including raw materials and finished goods. It encompasses everything from inventory tracking to inventory accounting and reporting. Good inventory management means having the correct amount of stock when needed, which helps save money and improve efficiency.

This blog discusses inventory management basics. It explains why inventory management is important for businesses. It also covers the key formulas needed to enhance inventory processes.

- Why is Inventory Management Important?

- What is the Inventory Management Process?

- Inventory Management Formulas

- Best Practices in Inventory Management

Why is Inventory Management Important?

Inventory management is the backbone of a successful business, impacting everything from financial health to customer satisfaction. Here’s why effective inventory management is crucial:

Financial Efficiency

Proper inventory management helps businesses avoid the costs associated with overstocking and stockouts. Overstocking ties up valuable capital in unsold goods, increasing storage and insurance costs. Conversely, stockouts can result in lost sales, rushed shipping charges, and dissatisfied customers. By reducing these issues, businesses can better manage their cost of goods sold and enhance overall financial efficiency.

Improved Customer Satisfaction

Effective inventory management ensures that businesses can meet customer demand promptly, without delays caused by stock shortages. This reliability builds customer trust and loyalty, leading to repeat business and positive word-of-mouth. Efficient order fulfillment processes also contribute to higher customer satisfaction.

Enhanced Decision Making

Accurate inventory tracking and reporting provide valuable insights into sales trends, demand patterns, and stock performance. Businesses can make informed decisions about purchasing, pricing, and promotions with detailed inventory analysis. Implementing ABC analysis allows businesses to prioritize inventory items, ensuring the most critical products are always in stock.

Risk Management

Businesses can reduce their exposure to theft, damage, and obsolescence by keeping accurate inventory records and implementing best practices. Regular audits and inventory analysis assist in identifying inconsistencies, avoiding losses, and protecting the company’s assets.

What is the Inventory Management Process?

Inventory management is a process that includes steps to keep the right amount of inventory. This helps businesses meet customer needs, save money, and work efficiently. Here’s an overview of the inventory management process:

- Demand Forecasting

- Inventory Planning

- Procurement

- Receiving and Inspection

- Storage and Organization

- Inventory Tracking

- Inventory Analysis

- Reordering

- Inventory Accounting

- Inventory Reporting

1. Demand Forecasting

Effective inventory management starts with accurate demand forecasting. This involves predicting future customer demand based on historical sales data, market trends, and seasonal fluctuations. Accurate forecasting helps businesses avoid overstocking and stockouts, ultimately optimizing the cost of goods sold (COGS).

2. Inventory Planning

Once demand is forecasted, inventory planning involves determining the optimal inventory levels to meet that demand. Setting reorder points, safety stock levels, and lead times ensures that inventory is supplied before it runs out. This planning is crucial for maintaining a balance between meeting customer demands and minimizing excess inventory.

3. Procurement

Procurement is the process of obtaining necessary inventory items from vendors. This stage entails negotiating with suppliers, placing orders, and ensuring the required inventory quantity is delivered on time. Efficient procurement processes help small businesses maintain good supplier relationships with suppliers and ensure timely order fulfillment.

4. Receiving and Inspection

When inventory arrives, it must be received and inspected for quality and accuracy. This includes checking the amounts against the orders, looking for any damage or issues, and updating inventory records. Proper inspection prevents future discrepancies and ensures quality inventory items are added to stock.

5. Storage and Organization

After receiving, inventory is stored in the warehouse. Proper organization is crucial to ensure that inventory is easily accessible and efficiently managed. This includes labeling, categorizing, and organizing items to facilitate easy retrieval. Efficient storage and organization directly impact the bottom line by reducing retrieval times and minimizing handling costs.

6. Inventory Tracking

Ongoing inventory tracking is essential to monitor stock levels and movements. You can use inventory management software to see real-time data on inventory levels, locations, and usage patterns. Barcode scanners and RFID technology can also be used to improve accuracy. Real-time tracking ensures businesses respond quickly to inventory needs and avoid overstocking or stockouts.

Related Read: How to manage inventory as a wholesale or retail business

7. Inventory Analysis

Regular inventory analysis helps businesses identify trends, assess performance, and make informed decisions. This includes analyzing turnover rates, identifying slow-moving or obsolete inventory, and assessing the efficiency of inventory processes. Techniques like ABC analysis help prioritize inventory management efforts by categorizing items based on their importance and value.

8. Reordering

Based on inventory levels and demand forecasts, businesses must reorder inventory to avoid stockouts. Automated reordering systems can streamline this process by generating purchase orders when inventory levels reach predetermined reorder points. This ensures continuous stock availability and improves overall warehouse efficiency.

9. Inventory Accounting

Effective inventory accounting involves tracking the cost of inventory, including purchasing, holding, and carrying costs. This step ensures accurate financial reporting and helps businesses understand the financial impact of their inventory. Proper inventory accounting practices contribute to more accurate financial statements and better decision-making.

Related Read: What Is Inventory in Accounting and How Is It Calculated?

10. Inventory Reporting

Regular inventory reporting provides insights into inventory performance and helps businesses make strategic decisions. Reports on inventory turnover, stock levels, and order fulfillment rates help identify areas for improvement. Comprehensive reporting ensures management has the information needed to optimize inventory management strategies.

Inventory Management Formulas

Effective inventory management relies on key formulas that help businesses maintain optimal stock levels and ensure smooth operations. These formulas empower firms to minimize costs, prevent stockouts, and ensure smooth operations. Let’s delve into key formulas to equip your inventory management arsenal:

Economic Order Quantity (EOQ)

This formula calculates the ideal order quantity, minimizing the total cost of holding inventory and placing orders. Consider it the sweet spot between having enough inventory in stock and avoiding needless storage costs.

Formula : EOQ = √((2DS)/H)

Where:

- D = Demand rate (units per period)

- S = Order cost (per order)

- H = Holding cost (per unit per period)

Reorder Point (ROP)

This formula tells you exactly when to reorder inventory to prevent stockouts. It considers your typical needs and the time it takes to receive them. This ensures that you always have sufficient stock available.

Formula : ROP = dL

Where:

- d = Average demand per period

- L = Lead time (in periods)

Inventory Turnover Ratio

This ratio reveals how efficiently your inventory is selling and being replaced. A higher ratio indicates faster inventory movement, potentially reducing storage costs.

Formula : Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory

Days Sales of Inventory (DSI)

This metric shows how long, on average, it takes to sell your entire inventory. A lower DSI suggests faster inventory turnover, potentially indicating a healthy stock control strategy.

Formula : DSI = Average Inventory / Cost of Goods Sold (COGS) x 365

Safety Stock

This buffer stock acts as a safety net, preventing stockouts caused by unexpected demand fluctuations or supply chain disruptions.

Formula : Safety Stock = (Z x σ) √L

Where:

- Z = Service level factor (desired level of service in terms of standard deviations)

- σ = Standard deviation of demand

- L = Lead time

Average Inventory

This calculation reveals the typical amount of stock you hold over a specific period.

Formula : Average Inventory = (Beginning Inventory + Ending Inventory) / 2

Gross Margin Return on Investment (GMROI)

This metric measures how profitable your inventory investment is by comparing the gross profit earned to the average inventory cost. A higher GMROI indicates a better return on your inventory investment.

Formula : GMROI = Gross Profit / Average Inventory Cost

Carrying Cost of Inventory

This formula calculates the inventory cost, including storage, insurance, and opportunity cost. It determines the expenses associated with holding inventory. These expenses include storage fees, insurance costs, and the potential loss of income from not investing the money elsewhere.

Formula : Carrying Cost = (Carrying Costs) / (Total Inventory Value) x 100

Fill Rate

This metric measures how often you can fulfill customer orders without stockouts. A higher fill rate translates to happier customers and fewer missed sales opportunities.

Formula : Fill Rate = (Total Units Delivered) / (Total Units Ordered) x 100

Lead Time Demand

This formula helps you determine the amount of product you should order to meet customer demand. It also considers the time it takes for a new shipment to arrive. By using this formula, you can ensure that you have enough inventory on hand to satisfy your customers.

Formula : Lead Time Demand = Lead Time x Average Daily Demand

Best Practices in Inventory Management

Effective inventory management is crucial for maintaining smooth operations, reducing costs, and ensuring customer satisfaction. Here are some best practices to optimize your inventory management process:

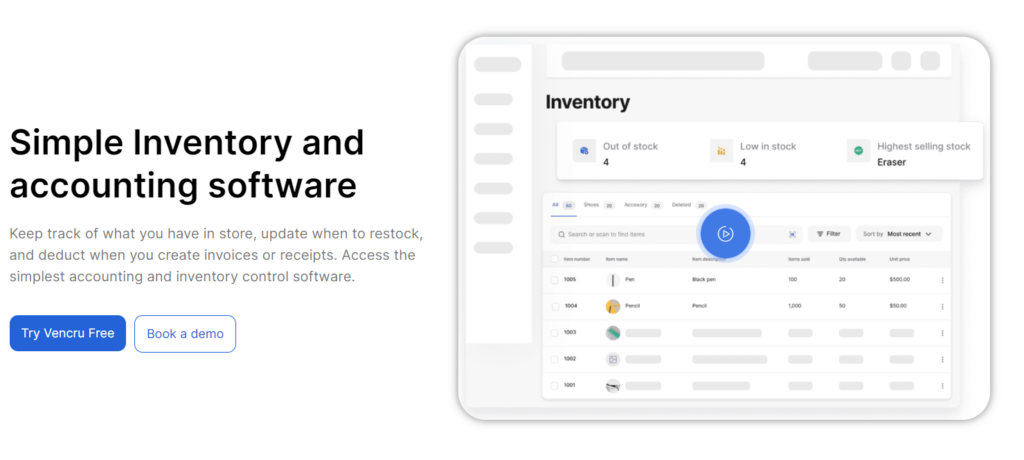

Utilizing Inventory Management Software

Adopting inventory management software can significantly streamline your inventory processes. These tools provide real-time tracking, automated reorder points, and comprehensive reporting. Popular software solutions include Vencru, which offers robust features for inventory analysis, tracking, and reporting.

Setting Reorder Points and Safety Stock Levels

Establishing reorder points ensures that you reorder inventory before it runs out. Safety stock is a buffer to protect against unexpected demand spikes or supply chain disruptions.

Training Staff and Promoting Best Practices

Well-trained staff are essential for effective stock management. Provide regular training on inventory management techniques, software usage, and warehouse best practices.

Implementing Continuous Improvement Processes

Regularly review and improve your stock management procedures. Seek feedback from your staff, identify areas for improvement, and introduce changes gradually.

Related Read: Inventory Management Best Practices

Elevate Your Inventory Management with Vencru

Vencru provides a robust inventory management system designed to meet the needs of businesses of all sizes. With Vencru, you can:

- Track Inventory in Real-Time: Gain real-time visibility into your stock levels, making inventory tracking easier and fulfilling orders faster.

- Automate Inventory Processes: Streamline your inventory processes with automated features that save time and reduce errors.

- Generate Detailed Reports: Access comprehensive reports that provide insights into your inventory performance, helping you make data-driven decisions.

Vencru is your go-to solution for effective inventory management. Implementing Vencru’s system will help you achieve inventory management best practices, ensuring your business runs smoothly and efficiently. Additionally, Vencru’s system helps small businesses manage their inventory items effectively, reducing the cost of goods sold and optimizing order fulfillment. With regular inventory counts, Vencru ensures your bottom line is positively impacted. Understanding what a stock management system is and utilizing Vencru’s advanced inventory data management solution will keep your business ahead of the competition.

Conclusion

Understanding inventory management and applying best practices is critical for any business wanting to improve its operations. Effective inventory management is the foundation of efficient business operations, spanning inventory tracking and analysis to accounting and reporting.

To ensure efficient and accurate stock management, use technology and regularly update procedures to match your business goals. Embracing management tools and technologies like inventory data software and ABC analysis can help small businesses improve the efficiency and accuracy of their inventory items and counts. Continuously updating procedures ensures they align with business goals, ultimately enhancing order fulfillment and impacting the bottom line. Efficient stock management practices directly influence the cost of goods sold and provide a robust management solution for any business.

Ready to transform your Inventory management and accounting? Explore Vencru here or book a demo.