Effective inventory management is a critical component of any successful business. It directly impacts your ability to meet customer demand, control costs, and maximize profitability. Yet, many businesses fall into common pitfalls that lead to inefficiencies, increased expenses, and customer dissatisfaction. Using advanced tools, such as Vencru’s inventory management system, can help you avoid inventory mistakes, efficiently manage different types of inventory, and optimize your business inventory, leading to better business management, improved handling of finished products, and a more effective point of sale process.

This guide will delve into five common inventory management mistakes and provide actionable solutions to avoid them. We’ll be discussing:

- The Importance of Inventory Management

- Key Benefits of Inventory Management

- Common Inventory Management Mistakes and Their Solutions

- Leveraging Vencru for Better Inventory Management

The Importance of Inventory Management

Effective inventory management ensures that the right products are available at the right time, in the right quantities, and at the right cost. It is about striking a balance between having enough inventory to meet customer demand without overstocking, which ties up capital and increases costs.

Poor inventory management can lead to stockouts, excess inventory, and ultimately, lost sales and dissatisfied customers.

Key Benefits of Effective Inventory Management

- Cost Reduction: By maintaining optimal inventory levels, businesses can reduce storage costs, minimize waste, and avoid the costs associated with stockouts.

- Improved Cash Flow: Efficient inventory management ensures that capital is not tied up in excess stock, allowing businesses to use their resources more effectively.

- Enhanced Customer Satisfaction: Having the right products available when customers need them enhances customer satisfaction and loyalty.

- Streamlined Operations: Effective inventory management leads to smoother operations, reducing the time and effort required to manage stock levels.

Related Read: Inventory Management Best Practices

Common Inventory Management Mistakes and Their Solutions

Effective inventory management is crucial for any business, but it’s not without its challenges. By avoiding common mistakes, you can optimize your inventory processes, reduce costs, and improve customer satisfaction. Here are some common inventory management mistakes and their solutions to help you optimize your inventory processes, reduce costs, and improve customer satisfaction.

1. Overstocking

Overstocking is a frequent mistake where businesses hold more inventory than necessary. This ties up capital, increases storage costs, and raises the risk of obsolescence, particularly for perishable goods.

For example, imagine a retail clothing store that stocks heavily on winter coats in anticipation of a cold season. If the winter turns out to be milder than expected, the store is left with an excess inventory of coats. This overstock not only occupies valuable storage space but also ties up capital that could have been invested in other, more in-demand products. Additionally, the longer the coats remain unsold, the higher the likelihood they become obsolete as fashion trends change, further reducing their value.

Solution

- Just-in-Time (JIT) Inventory: JIT inventory management involves ordering and receiving inventory for production and sales only as needed to meet customer demand. This approach minimizes the costs associated with holding excessive inventory.

- ABC Analysis: Classify inventory into three categories (A, B, and C) based on their importance. Focus on optimizing inventory levels for high-value items (A), while keeping a reasonable stock of medium (B) and low-value items (C).

- Regular Audits: Conduct regular inventory audits to identify excess stock and adjust your purchasing strategies accordingly.

2. Understocking

Understocking occurs when businesses do not maintain sufficient inventory levels to meet customer demand. This issue can lead to stockouts, lost sales, and unhappy customers, ultimately harming your business’s reputation and bottom line. Understocking is often a result of inadequate demand forecasting, poor inventory tracking, or supply chain disruptions

For example, a business that sells trendy clothing items. During the summer, they experience a high demand for swimsuits. However, due to inadequate demand forecasting and poor inventory management, they underestimated the swimsuits needed. As a result, they run out of stock just as the peak season begins. This leads to lost sales and disappointed customers who turn to competitors to fulfill their needs.

Solution

- Demand Forecasting: Utilize historical sales data, market trends, and seasonality to predict future inventory needs accurately. Vencru provides tools to help you analyze these trends and make informed decisions.

- Safety Stock: Maintain a safety stock level for high-demand products to buffer against unexpected spikes in demand or supply chain disruptions.

- Automated Reordering: Set up automated reordering processes with Vencru to ensure timely replenishment of inventory, reducing the risk of stockouts.

3. Lack of Inventory Tracking

Failing to track inventory accurately is a common mistake that can lead to significant operational challenges. When businesses do not have an accurate count of their inventory, discrepancies between actual stock levels and inventory records become inevitable. This can result in several issues, such as:

- Inaccurate Order Fulfillment: Customers may receive incorrect items or quantities, leading to returns and dissatisfaction.

- Stockouts: Without precise tracking, businesses may run out of stock unexpectedly, causing delays in fulfilling orders and lost sales opportunities.

- Overstocking: Conversely, businesses might overorder products, leading to excessive inventory that ties up capital and increases storage costs.

- Inefficient Supply Chain Management: Inaccurate inventory data can disrupt the supply chain, making it difficult to plan and manage production schedules effectively.

Consider a small retail business that relies on manual inventory counts and spreadsheets to track stock levels. During a busy holiday season, the business experiences a surge in orders. Due to the lack of an automated inventory tracking system, the manual counts become outdated quickly, and employees struggle to keep up with the influx of sales and deliveries.

Solution

- Barcode Scanning: Implement barcode scanning to automate the process of tracking inventory movements. This reduces human error and ensures accurate records.

- RFID Tags: For larger operations, consider using RFID tags, which allow for real-time tracking and bulk scanning of items.

- Inventory Management Software: Leverage Vencru’s real-time inventory tracking capabilities to monitor inventory levels and movements continuously, ensuring accuracy and reducing errors. Real-time inventory tracking offers numerous benefits, including improved accuracy, faster processing times, and enhanced visibility.

4. Ignoring Dead Stock

Deadstock refers to inventory that hasn’t sold and is unlikely to sell, taking up valuable storage space and tying up capital. Businesses often overlook this issue, either because they are too focused on high-turnover items or because they lack effective inventory review processes.

For example, a clothing retailer might order a large batch of seasonal items like winter coats. If these items don’t sell as expected during the winter season, they become dead stock by spring. Keeping these coats in inventory ties up storage space and capital, preventing the retailer from stocking new, in-season items that could sell better. Over time, the coats may become outdated, further reducing their chances of being sold.

Solution

- Inventory Review: Regularly analyze your inventory to identify dead stock. Use Vencru’s detailed reports to gain insights into slow-moving items.

- Promotions and Discounts: Offer discounts or bundle deals to move dead stock quickly.

- Donation or Liquidation: Donate obsolete items to charities or liquidate them to free up storage space and recover some capital.

5. Poor Supplier Management

Poor supplier management can significantly disrupt your inventory management process and overall supply chain efficiency. This issue often arises from relying on unreliable suppliers or failing to maintain and evaluate supplier relationships. Such negligence can lead to delays, quality issues, and inconsistencies in your supply chain, directly affecting your ability to meet customer demand.

Imagine a small electronics manufacturing company that heavily relies on a single supplier for critical components. The supplier often fails to meet delivery deadlines due to its logistical challenges. Consequently, the manufacturing company frequently faces production delays and stockouts, causing them to miss customer orders and tarnish their reputation. This situation illustrates poor supplier management.

Solution

- Supplier Evaluation: Regularly assess supplier performance based on key criteria such as delivery times, product quality, reliability, and cost-effectiveness. Use performance metrics and supplier scorecards to keep track of supplier performance over time.

- Negotiate Favorable Terms: Negotiating favorable terms with suppliers can help improve the reliability and cost-effectiveness of your supply chain. This includes discussing lead times, pricing, payment terms, and order quantities.

- Diverse Supplier Base: Avoid over-reliance on a single supplier. Instead, build a diversified supplier base to mitigate risks associated with supplier disruptions. Having multiple suppliers ensures that if one fails, you have alternatives to fall back on, minimizing potential delays.

Leveraging Vencru for Better Inventory Management

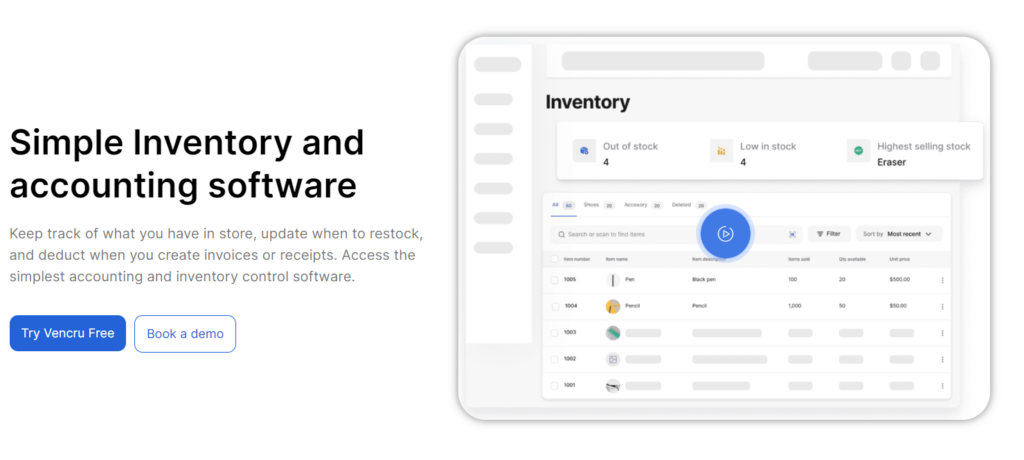

Avoiding these common inventory management mistakes is easier with the right tools. Vencru offers a comprehensive inventory management solution tailored to the needs of businesses. Here’s how Vencru can help:

1. Real-Time Inventory Tracking: Monitor inventory levels in real time to prevent overstocking and understocking. With accurate and up-to-date information, you can make informed decisions and respond quickly to changes in demand.

2. Automated Reordering: Ensure timely replenishment of inventory to avoid stockouts. Vencru’s automated reordering feature simplifies the process, ensuring you always have the right amount of stock on hand.

3. Detailed Reports: Gain insights into sales trends and inventory movements to make informed decisions. Vencru’s detailed reporting tools help you analyze your inventory data, identify patterns, and optimize your stock levels.

4. Supplier Management: Keep track of supplier performance and streamline procurement processes. With Vencru, you can monitor supplier reliability, negotiate better terms, and ensure timely delivery of goods.

5. User-Friendly Interface: Easily manage your inventory with Vencru’s intuitive and easy-to-use platform. Whether you’re a small business or a large enterprise, Vencru’s user-friendly interface makes inventory management simple and efficient.

Conclusion

Effective inventory management is critical for the success of any business. Avoiding common issues like overstocking, understocking, and poor supplier management will help you optimize your inventory processes and increase your bottom line. Leveraging tools like Vencru can help you stay on top of your inventory and ensure your business runs smoothly.

Start using Vencru here or book a demo to take control of your inventory and drive your business success.

Related Content