Effective inventory management strategies are crucial for the success of any business, especially to manage small businesses. Proper stock management ensures businesses can meet customer demand without overstocking or understocking products, preventing lost sales and increased costs.

In this blog post, we will explore how inventory management works for small businesses, their challenges, common inventory mistakes, and strategies for implementing effective inventory management. We will also discuss the importance of barcoding and organizing inventory, and how leveraging tools like Vencru can streamline these processes. We will be discussing:

- How Does Inventory Management Work for Small Businesses?

- Common Small Business Inventory Mistakes

- How to Implement Inventory Management as a Small Business

- Small Businesses and Barcoding

- Organizing Inventory for Small Businesses

- Leveraging Vencru for Effective Inventory Management

How Does Inventory Management Work for Small Businesses?

Inventory management involves tracking and managing a company’s inventory, which includes raw materials, work-in-progress products, and finished goods. For small businesses, inventory management is about ensuring that they have the right amount of stock at the right time to manage customer demand. This process includes ordering, storing, tracking, and controlling inventory.

Related Read: What is Inventory Management: Definition, and Process

Key Components of Inventory Management for Small Businesses

- Inventory Tracking: Accurate inventory tracking involves maintaining up-to-date records of inventory levels. This practice enables businesses to know what products are in stock, what needs to be reordered, and which items are running low or out of stock.

- Demand Forecasting: Predicting future customer demand is crucial for maintaining optimal inventory levels. Businesses can analyze historical sales data, market trends, and seasonal fluctuations to forecast demand more accurately. This helps prevent understocking or overstocking scenarios, ensuring products are available when customers need them.

- Reordering: Efficient inventory management includes setting reorder points and quantities. Reorder points are thresholds that trigger inventory restocking once it reaches a specified minimum level. This proactive approach helps businesses avoid stockouts and maintain a consistent supply chain flow.

- Storage and Organization: Organizing inventory effectively is essential for maximizing warehouse space and streamlining operations. Proper storage techniques, such as using shelves, bins, or pallets, ensure that items are easily accessible and properly arranged based on their demand and storage requirements.

- Inventory Auditing: Regular inventory audits are necessary to verify the accuracy of inventory records. Cycle counting, a method of counting subsets of inventory regularly, helps identify discrepancies promptly. This proactive approach minimizes errors in inventory management and ensures data integrity.

- Supply Chains and Lead Times: Understanding supply chain dynamics and lead times is crucial for managing inventory effectively. By working closely with suppliers and predicting lead times, businesses can reduce the risk of disruptions and maintain a steady inventory flow.

Why is Inventory Management a Challenge for Small Businesses?

Inventory management can be particularly challenging for small businesses due to limited resources, lack of expertise, and the dynamic nature of demand. Here are some common challenges faced by small businesses in inventory management:

- Limited Capital: Retail and wholesale businesses must prioritize effective inventory management to ensure funds are used efficiently, especially given their limited capital for inventory investment. Keeping the right amount of stock without overspending is essential. Implementing robust inventory strategies and leveraging inventory management techniques helps achieve this balance. Using real-time data and cycle counting can prevent excess inventory and ensure accurate inventory data

- Space Constraints: Limited storage space makes it challenging to store inventory efficiently. This often results in excess inventory, tying up capital and space that could be used more effectively.

- Manual Processes: Many small businesses rely on manual processes for tracking inventory, which can be time-consuming and prone to errors. Implementing automated inventory management solutions can help mitigate these issues by providing real-time data and accurate inventory tracking.

- Lack of Expertise: Small business owners may lack expertise in inventory management, leading to inefficient practices. Investing in training or consulting services can introduce better inventory management strategies and techniques, such as cycle counting and inventory turnover analysis, to improve overall efficiency.

- Fluctuating Demand: Small businesses often face fluctuating demand patterns, making it challenging to forecast accurately. This can lead to either stockouts or excess inventory, both of which impact the bottom line. Utilizing inventory data and implementing inventory management techniques like lead time analysis can help small businesses better align their inventory levels with demand.

Related Read: Inventory Management Best Practices: Guide

Common Small Business Inventory Mistakes

Small businesses often make several common inventory management mistakes that can negatively impact their operations and profits. Understanding these mistakes can help avoid them and improve overall efficiency.

Overstocking Inventory

Overstocking occurs when a business orders more inventory than it can sell within a reasonable period. This ties up capital, increases storage costs, and can lead to obsolete inventory. Demand forecasting and setting reorder points based on sales data and market trends would help to eliminate overstocking.

Understocking Inventory

Understocking happens when a business does not order enough inventory to meet customer demand, leading to stockouts and lost sales. An inventory management software would track inventory levels in real-time and set up alerts for low stock to ensure timely reordering.

Lack of Inventory Tracking

Not tracking inventory accurately can result in discrepancies between actual stock levels and recorded data, leading to stockouts or overstocking. Small businesses can implement a stock management system that provides real-time tracking and updates inventory levels automatically.

Ignoring Inventory Audits

Regular inventory audits are essential for ensuring accuracy and identifying discrepancies. Ignoring audits can lead to undetected issues that affect inventory levels and financial records. Businesses should schedule regular inventory audits and use audit tools to streamline the process to maintain accurate records.

Inefficient Storage and Organization

Poor inventory organization can lead to difficulty in locating products, increased picking times, and errors in order fulfillment. Organizing inventory efficiently, labeling storage areas, and using barcoding would improve accuracy and efficiency.

How to Implement Inventory Management as a Small Business

Implementing effective inventory management requires a strategic approach and the right tools. Here are some steps small businesses can take to improve their stock management processes:

Step 1: Assess Your Current Inventory Management Practices

Evaluate your current inventory management practices to identify areas for improvement. This includes reviewing how you track inventory, forecast demand, reorder stock, and organize storage.

Step 2: Invest in Inventory Management Software

Investing in inventory management software can significantly improve accuracy and efficiency. Look for software that offers features such as real-time tracking, demand forecasting, automated reordering, and integration with other business systems.

Step 3: Implement Barcoding

Barcoding can streamline inventory tracking and reduce errors. Implement a barcoding system to label products and storage areas, and use barcode scanners to update inventory levels automatically.

Step 4: Organize Your Inventory

Efficiently organize your inventory to locate and manage products easily. Label storage areas, group similar items, and implement a first-in, first-out (FIFO) system to ensure you use older inventory first. This effective management technique helps streamline your inventory strategies, reduces excess inventory, and improves inventory turnover.

Step 5: Train Your Staff

Ensure that your staff is properly trained in inventory management practices and the use of inventory management software and tools. This will improve accuracy and efficiency in managing inventory.

Step 6: Conduct Regular Audits

Schedule regular inventory audits to verify stock levels and identify discrepancies. Use audit tools to streamline the process and maintain accurate records.

Step 7: Monitor and Adjust

Monitor your inventory management processes regularly and make adjustments as needed. This includes reviewing demand forecasts, reorder points, and storage practices to ensure optimal inventory levels.

Small Businesses and Barcoding

Barcoding is a powerful tool for small businesses to improve stock management. It involves labeling products and storage areas with barcodes, which can be scanned to update inventory levels automatically. Here are some benefits of implementing barcoding for small businesses:

Benefits of Barcoding

- Improved Accuracy: Barcoding reduces manual data entry errors, ensuring accurate inventory records. This accuracy is crucial for effective management and maintaining the integrity of your inventory data.

- Faster Processing: Scanning barcodes speeds up inventory tracking, reducing the time required to update stock levels. This efficiency can significantly improve order fulfillment processes, ensuring timely deliveries.

- Enhanced Efficiency: Barcoding streamlines order fulfillment by making it easier to locate and pick products. This speeds up the process and reduces the likelihood of picking errors, enhancing overall customer satisfaction.

- Real-Time Updates: Barcoding provides real-time updates on inventory levels, allowing for timely reordering and reducing the risk of stockouts. This real-time data is essential for managing lead times and ensuring that you always have the right amount of inventory on hand.

Implementing Barcoding

To implement barcoding in your small business, follow these steps:

- Choose a Barcoding System: Select a barcoding system that suits your business needs. This includes barcode printers, scanners, and software.

- Label Products and Storage Areas: Label all products and storage areas with barcodes. Ensure that labels are clear and durable.

- Train Staff: Train your staff on how to use barcode scanners and the barcoding system. This includes scanning barcodes to update stock levels and track product movements.

- Integrate with Inventory Management Software: Integrate your barcoding system with your inventory management software to automate updates and ensure real-time tracking.

Organizing Inventory for Small Businesses

Effective inventory organization is essential for efficient operations and accurate small business inventory management. Here are some tips for organizing stock in small businesses:

- Label Storage Areas: Clearly label storage areas to make it easy to locate products. Use signs, labels, and color coding to identify different sections.

- Group Similar Items Together: Group similar items together to make it easier to find and manage inventory. This includes organizing products by category, size, or type.

- Implement a FIFO System: Use a first-in, first-out (FIFO) system to ensure that older inventory is used first. This lowers the chance of having outdated inventory and makes sure products are sold before they expire.

- Use Shelving and Bins: Use shelving and bins to organize inventory and maximize storage space. Ensure that items are easily accessible and properly labeled.

- Regularly Review and Adjust: Regularly review your inventory organization practices and make adjustments as needed. This includes rearranging storage areas, updating labels, and relocating products based on demand.

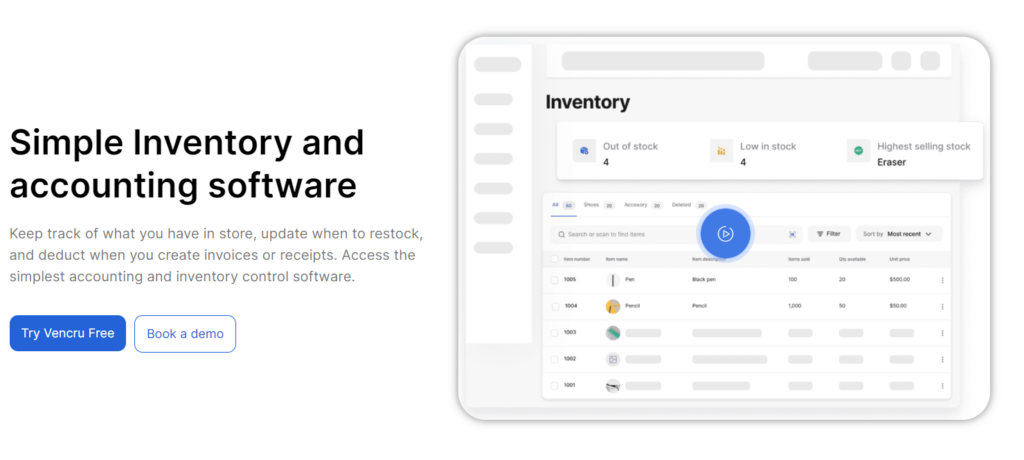

Leveraging Vencru for Effective Inventory Management

Vencru is an advanced inventory management tool designed to help small businesses streamline their inventory processes and improve accuracy. Here are some benefits of using Vencru:

- Improved Accuracy: Vencru’s real-time tracking and automated updates reduce the risk of discrepancies and errors.

- Enhanced Efficiency: Vencru streamlines inventory management processes, saving time and reducing manual effort.

- Cost Savings: By maintaining optimal inventory levels and reducing the risk of overstocking and stockouts, Vencru helps businesses save on storage and carrying costs.

- Better Decision-Making: Vencru’s analytics and reporting tools provide valuable insights, helping businesses make informed decisions about inventory management.

Conclusion

Good inventory management is crucial for small businesses to succeed. Knowing how it works, identifying common challenges and mistakes, and using best practices help small businesses streamline stock processes and boost efficiency. Leveraging advanced tools like Vencru can streamline stock management by providing real-time data tracking, automated reordering, and powerful analytics.

These features help businesses implement effective inventory management strategies, maintain optimal stock levels, and make informed decisions. Implementing barcoding and organizing inventory efficiently can also enhance accuracy and efficiency. Small businesses can reduce costs, improve customer satisfaction, and drive long-term success by focusing on inventory management.

Start using Vencru here or book a demo to take control of your inventory and drive your business success.

Related Content