Inventory is the lifeblood of any business. It includes all the goods and materials a business holds for resale. Thus, inventory management effectively is crucial for optimizing retail or wholesale operations, reducing costs, and maximizing profits. This guide will show you how to manage inventory effectively. It will explain why inventory management is important and the advantages it brings. It will also provide strategies and top tools to make the process easier.

- What is inventory?

- Types of inventory in wholesale and retail business

- Benefits of inventory management

- How to manage inventory as a wholesaler or retailer?

- Inventory management on Vencru

What is Inventory?

Inventory refers to the products, goods, or materials available to customers. It includes all items held by the business for resale or distribution. Inventory is crucial for companies as it affects their ability to meet customer demand, make money, and be profitable.

The sourcing of inventory differs between a wholesaler and a retailer. For wholesalers, inventory is typically sourced from manufacturers or suppliers. These items are often purchased in bulk and stored in warehouses or distribution centers. They are then sold to retailers or other businesses.

Retail businesses keep products in stock to sell directly to customers in stores or online. They may also include items used in-house for making products, like bakery ingredients or hardware store components.

Retailers must manage their inventory carefully. They need to ensure they have enough stock for customers. At the same time, they should avoid having too much old stock. Old stock can take up space and tie up money.

In both scenarios, effective inventory management is essential for optimizing retail or wholesale business operations and maximizing profits. It involves various activities such as inventory tracking, replenishment, forecasting, and order fulfillment. This ensures the right products are available in the right quantities at the right time.

Related Read: 7 tips for optimizing wholesale inventory

Types of Inventory in wholesale and retail business

In wholesale and retail businesses, inventory can be classified into several types. These types are based on the products’ nature, stage in the supply chain, and intended use. Here are some common types:

- Raw Materials

- Work-in-Progress (WIP)

- Finished Goods

- Merchandise Inventory

- Seasonal Inventory

- Perishable Inventory

Raw Materials:

Raw materials are the basic components or inputs used in the production process to manufacture finished goods. In wholesale businesses, raw materials may include commodities, minerals, or agricultural products purchased in bulk from suppliers. In retailers, raw materials are less common. Still, they may consist of items used in-house for manufacturing or assembling products (e.g., bakery ingredients or hardware store components).

Work-in-Progress (WIP):

Work-in-progress inventory consists of partially completed goods that are being manufactured or assembled. In wholesale businesses, WIP may include products undergoing assembly according to customer specifications. In retail businesses, WIP may include items undergoing packaging, labeling, or assembly before being placed on store shelves.

Finished Goods:

Finished goods inventory comprises products that are ready for sale to customers. In wholesale businesses, finished products may include packaged or bulk products sourced from manufacturers or suppliers. In retail businesses, finished goods are the primary inventory items for purchase by end consumers in stores or online.

Merchandise Inventory:

Merchandise inventory refers to the assortment of goods retailers hold for resale to customers. In wholesale businesses, merchandise inventory may comprise various products sourced from suppliers and manufacturers. In retail stores, merchandise inventory refers to the products available for customers to purchase in-store or online.

Seasonal Inventory:

Seasonal inventory comprises products in demand only during specific times of the year, such as holidays or peak seasons. In wholesale businesses, seasonal inventory may include products tailored to meet the needs of retailers during specific sales periods. In stores, seasonal inventory includes items like winter clothes or holiday decorations that match the time of year.

Perishable Inventory:

Perishable inventory includes goods with a limited shelf life or expiration date. Examples include fresh produce, dairy products, and drugs. In wholesale businesses, perishable inventory may include products that require careful handling and storage to maintain quality. In retail businesses, perishable inventory must be managed efficiently to minimize waste and ensure product freshness for customers.

While the types of inventory may overlap between wholesale and retail businesses, their management strategies and priorities often differ. Wholesale businesses focus on optimizing supply chain efficiency, minimizing carrying costs, and fulfilling bulk orders from retailers. In contrast, retail businesses prioritize maintaining adequate stock levels to meet customer demand, maximizing sales opportunities, and enhancing the shopping experience.

What is Stock Management?

Inventory management, or stock management, involves overseeing and controlling the movement of goods and materials in and out of a business (wholesale or retail). It involves tracking stock levels, monitoring stock movement in and out, and optimizing inventory turnovers. This ensures the right products are available in the right quantities at the right time.

Benefits of wholesale inventory management

For wholesale and retail businesses, effective stock management is crucial for several reasons:

- Minimizing Stockouts and Overstock

- Meeting Customer Demand

- Optimizing Cash Flow

- Preventing Obsolescence and Spoilage

Minimizing Stockouts and Overstock:

Wrong inventory levels due to overstocking cost retailers more than $300Bn in revenue annually. Proper inventory management helps wholesale businesses balance avoiding stockouts (i.e., running out of products) and minimizing overstock (i.e., excess inventory). This ensures that capital is not tied up in surplus inventory. This leads to markdowns, discounts, or losses due to missed sales opportunities.

For instance, a wholesaler that accurately forecasts demand can avoid the costs associated with excess inventory storage and disposal. They are also less likely to run sales due to overstocking.

Meeting Customer Demand:

By maintaining sufficient stock levels of popular products, businesses can fulfill customer orders promptly, thereby preventing markdowns and enhancing customer satisfaction and loyalty.

A store that consistently has popular items available and satisfies customers is more likely to receive repeat business and positive reviews. Customers are more likely to return and recommend the store to others if their needs are consistently met. In turn, this can lead to increased sales and a positive reputation for the store.

Optimizing Cash Flow:

Good stock management helps businesses save money. It does this by keeping inventory less and reducing insurance and storage costs. This ultimately increases cash flow. By turning inventory over quickly, businesses can free up capital to invest in other business areas, such as marketing or expansion initiatives.

Preventing Obsolescence and Spoilage:

Timely inventory management helps prevent the risk of product obsolescence or spoilage, particularly for perishable or seasonal items. Businesses can track stock levels and turnover rates to find products that are not selling well or have expired. This helps them take action to reduce losses.

How to manage inventory as a wholesaler or retailer?

Managing inventory can improve customer experience, reduce stock shortages, and boost cash flow and profits for wholesale and retail businesses.

- Build Strong Supplier Relationships

- Forecast Demand and Set Reorder Points

- Use Inventory Management Software

- Maintain detailed logs of all inventory movements

- Monitor Top-Selling and Low-Performing Products

- Track Inventory Performance Metrics

- Perform Physical Stock Counting

Build Strong Supplier Relationships:

Developing strong relationships with reliable suppliers ensures timely and cost-effective procurement. Negotiating favorable terms can lead to discounts, bulk pricing, or extended payment terms, reducing purchasing costs.

In addition, building trust with suppliers can result in priority access to inventory during high-demand periods, preventing stockouts and maintaining customer satisfaction.

To develop strong relationships, communicate regularly with suppliers to understand their capabilities, lead times, and pricing structures. In addition, plan purchases based on demand forecasts and negotiate agreements that benefit both parties. Strong supply chain management is key to managing stock levels.

Forecast Demand and Set Reorder Points:

Analyzing historical sales data and market trends allows businesses to predict future demand accurately. Establishing reorder points for each product ensures timely replenishment before inventory levels run low.

In addition, accurate forecasting helps prevent stockouts and overstock situations, optimize stock levels, and reduce carrying costs.

To achieve this, use stock management software to analyze sales trends and forecast demand for each product SKU. Set reorder points based on lead times, sales velocity, and desired safety stock levels.

Use Inventory Management Software:

Inventory management software assists businesses in monitoring inventory levels, movements, and locations in real-time. This ensures that records are accurate and management is efficient. Features such as barcode scanner or RFID tagging enhance accuracy and tracking.

Efficient stock management streamlines operations, minimizes errors, and improves decision-making by providing real-time visibility into stock levels and movements.

Choose retail inventory management software that is easy to use and meets your business needs. Make sure it can integrate well with other systems, such as a point-of-sale (POS) system for tracking sales.

Related Read: Best inventory management software for wholesale businesses

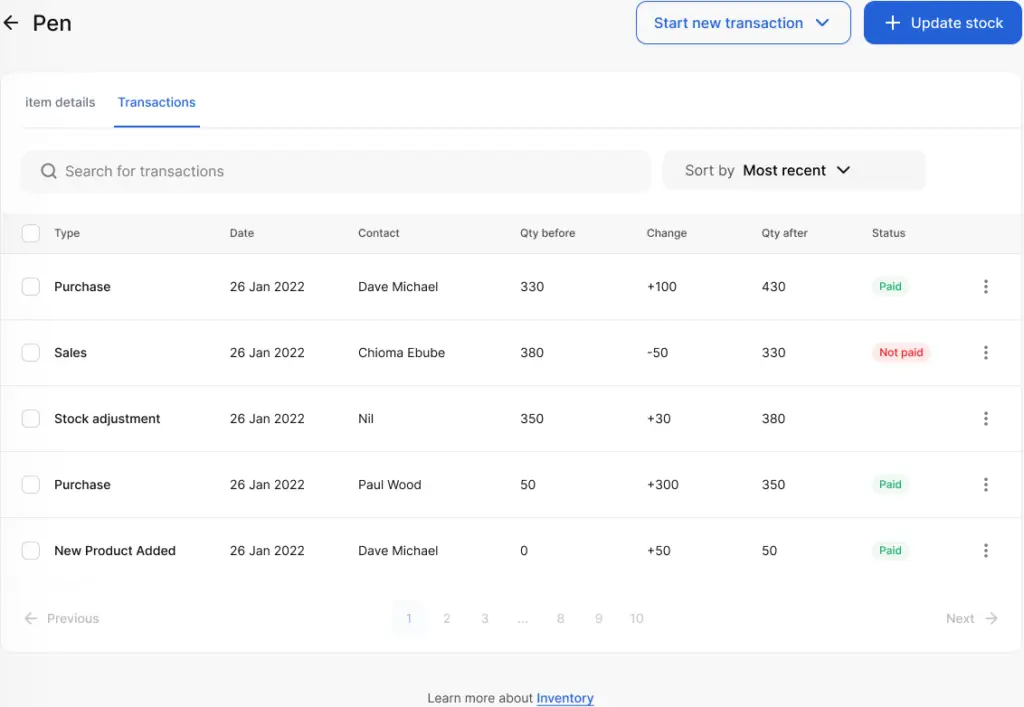

Maintain Detailed Logs of Inventory Movements:

Logging all inventory movements, including inflows from vendor purchases and outflows from sales, ensures stock is traceable. Tracking returns and transfers between locations further enhances transparency.

Detailed inventory logs enable businesses to identify discrepancies, monitor stock movements, and maintain accurate records for regulatory compliance and auditing purposes.

Implement standardized procedures for documenting all inventory transactions, including timestamps, quantities, and locations. Inventory management software can be used to automate stock movement tracking for wholesale or retail businesses, saving you time while ensuring data accuracy.

Monitor Top-Selling and Low-Performing Products:

Regularly reviewing sales data helps identify top-selling products and slow movers. Adjusting stock levels based on demand ensures optimal stock levels and avoids overstocking or stockouts.

Monitoring product performance also allows businesses to allocate resources effectively, prioritize inventory replenishment, and maximize sales opportunities.

Analyze sales reports and inventory turnover rates to identify top-selling and low-performing products. Adjust inventory levels accordingly and reallocate resources from slow-moving items to high-demand products.

Track Inventory Performance Metrics:

Monitoring key performance indicators (KPIs) such as inventory turnover, carrying cost, and order accuracy provide insights into inventory performance. In addition, it helps identify areas for improvement.

Tracking inventory metrics allows wholesale or retail businesses to assess the efficiency and effectiveness of their inventory management practices, enabling data-driven decision-making and continuous improvement.

Utilize stock management software to generate real-time reports and dashboards that track KPIs. Set benchmarks and targets for each metric and regularly review performance against these benchmarks.

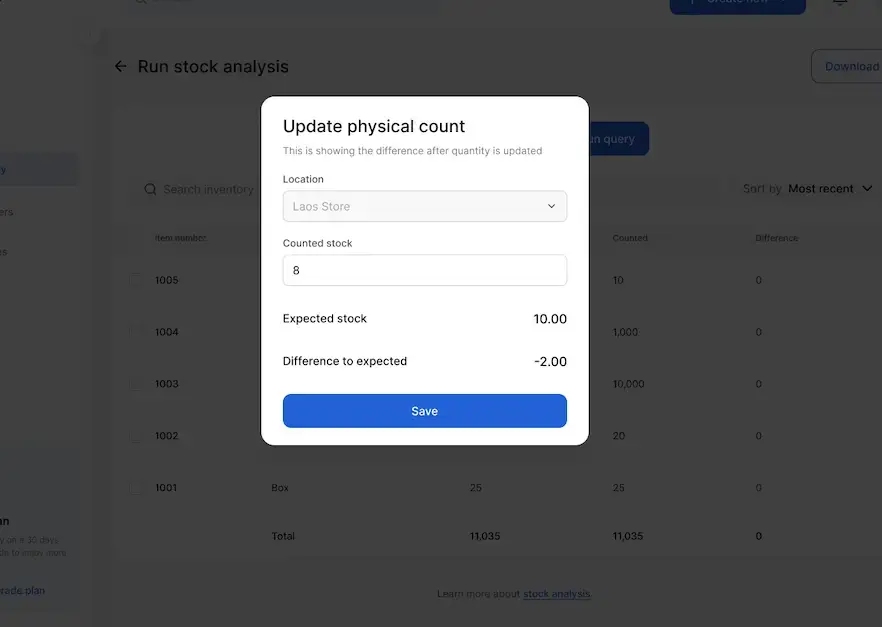

Perform Regular Physical Stock Counts:

Conducting regular physical inventory counts verifies system accuracy and identifies discrepancies between recorded and actual stock levels. This ensures data integrity and minimizes the risk of stockouts or overstock situations.

Physical stock counts help maintain inventory accuracy, prevent shrinkage, and comply with regulatory requirements. They also provide an opportunity to identify and address any issues with inventory management processes.

Schedule periodic physical inventory counts based on business needs and industry best practices. Use inventory management software to reconcile physical counts with recorded inventory levels and promptly investigate discrepancies. Check inventory often for damage or defects. Put procedures in place to reduce losses, like storing and handling items correctly.

Inventory management on Vencru

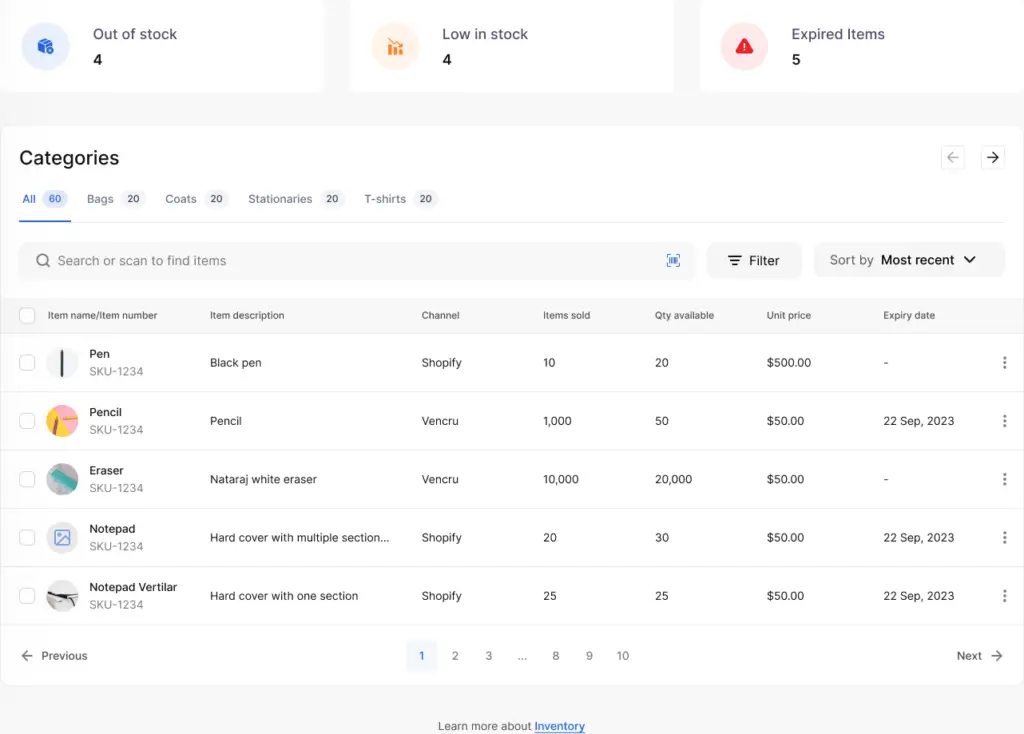

Vencru has an easy-to-use inventory management tool for wholesale or retail businesses. It has key features to make operations smoother and increase profits. Here’s an overview of its key functionalities:

- Real-Time Stock Tracking

- Stock Movement

- Stock Counting

- Multi-Location Management

- Inventory valuation and Inventory costing

- Financial Reporting

Real-Time Stock Tracking:

Monitor stock levels in real time to ensure optimal inventory levels and prevent stockouts or overstocking. Receive automated alerts for low stock levels to replenish inventory promptly and avoid disruptions in sales.

Track products’ expiry dates to prevent wastage and ensure the sale of fresh inventory. Receive notifications for upcoming expiries, allowing proactive management and timely sales promotions.

Stock Movement:

Track all stock movements, including sales transactions, incoming purchase orders, and supplier shipments. Maintain accurate records of stock activities to ensure no losses.

Stock Counting:

Perform regular stock counts to reconcile physical inventory with system records and identify discrepancies. By conducting systematic stock counts at scheduled intervals, you can ensure inventory accuracy and minimize errors.

Multi-Location Management:

With Vencru’s multi-location feature, you can manage inventory across multiple warehouses or locations. You can track inventory movement between locations, perform stock transfers, and analyze sales and product performance by location.

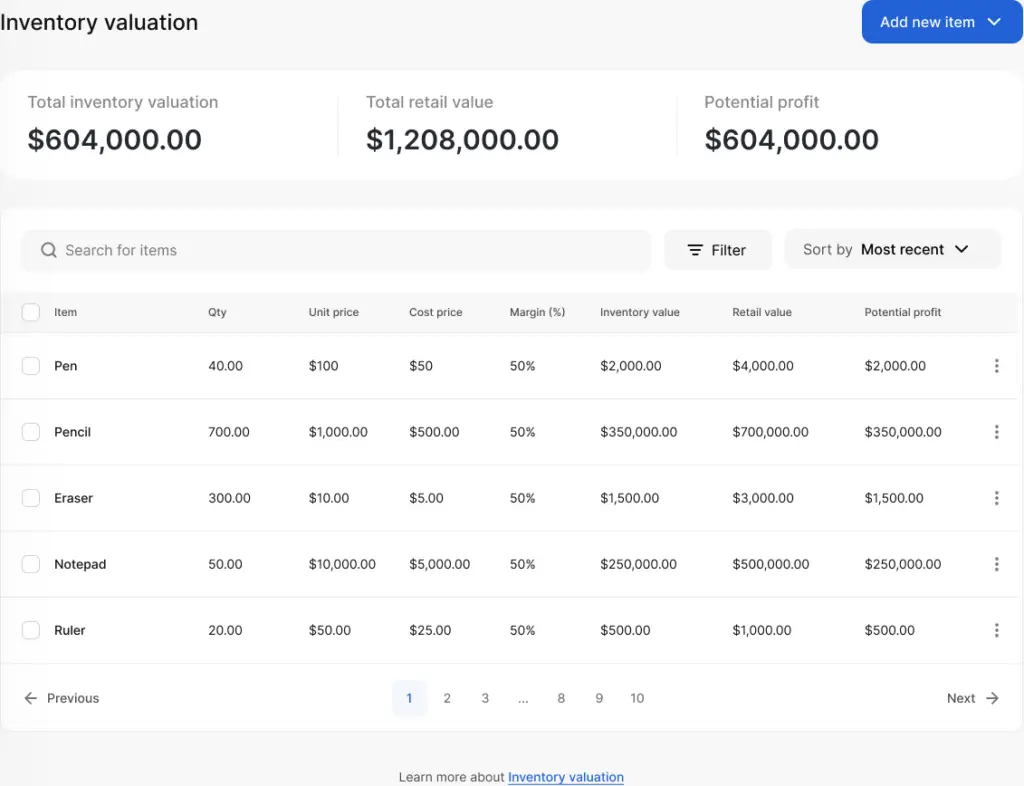

Inventory Valuation and Inventory Costing:

Automate inventory valuation and profit margin monitoring to maximize profits. Gain insights into your top-selling and under-performing products.

Automatically track the cost of goods sold (COGS) to accurately calculate profits and determine the financial health of your business. Generate detailed reports on COGS to facilitate informed decision-making and strategic planning.

Financial Reporting:

Uncover actionable insights with comprehensive reports. Analyze your business inventory performance, and sales data by product, category, location, and more. Gain a holistic view of your business health with key financial metrics, allowing you to optimize your product mix, cash flow, and overall financial performance.

Related Read: Chart of Accounts for Wholesale Distributors

Conclusion

Effective inventory management is critical for maintaining a positive cash flow and expanding your business. You can ensure that your business has the resources it requires to thrive by reducing stockouts, optimizing cash flow, and preventing losses. Keeping accurate inventory records, cultivating strong supplier relationships, and leveraging powerful tools are the keys to realizing these benefits.

Inventory software, such as Vencru, enables you to make data-driven decisions, streamline operations, and ultimately achieve sustainable business success.

Ready to explore Vencru? Get started here or book a demo